Premium Quality 3D CAD Files for Your Engineering Projects

3D CAD Files Collections Info for 3D CAD Engineers Hygienic Tube couplings

Design hygienic process systems: The main coupling types compared

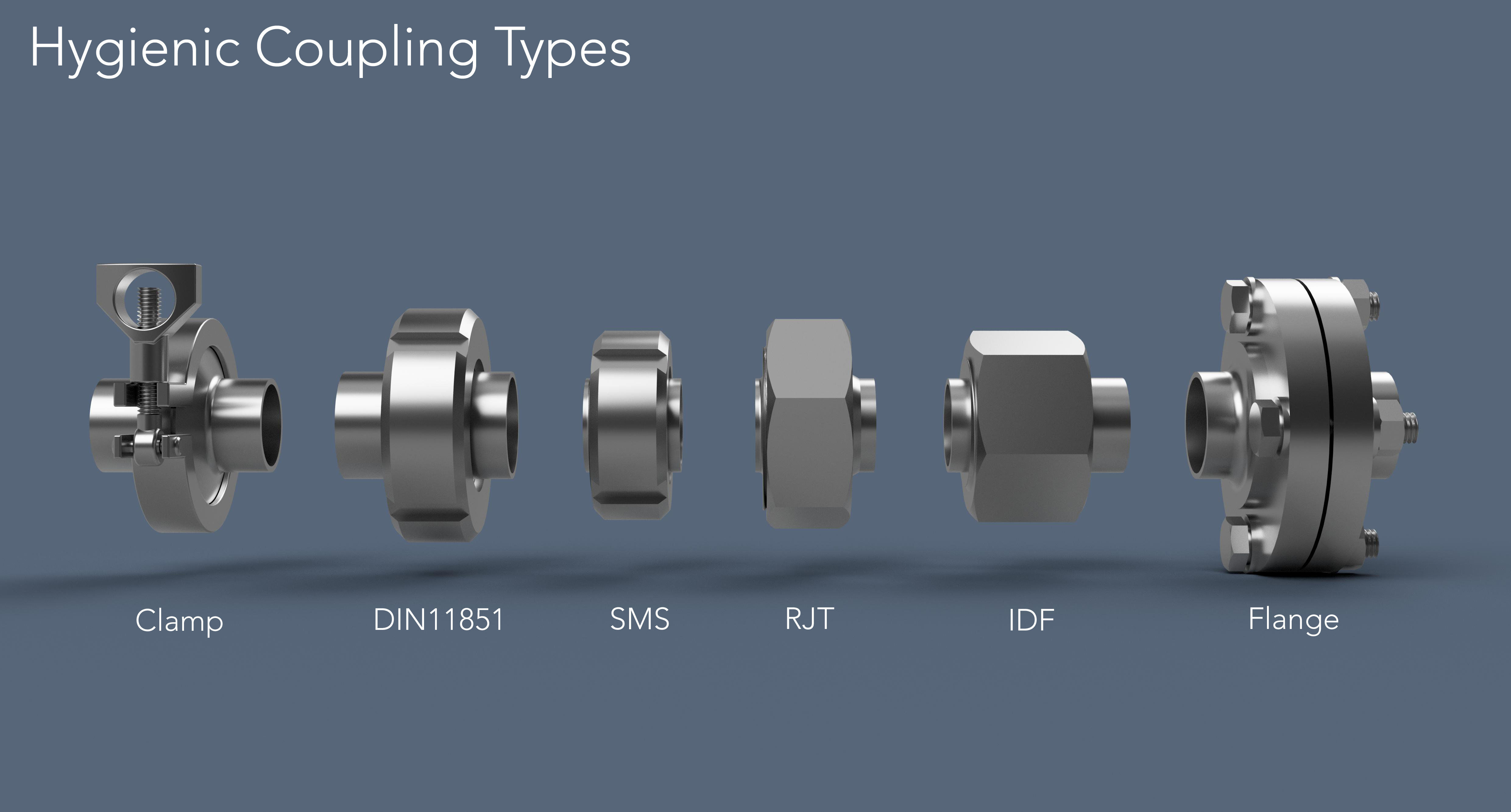

The Six Key Hygienic Union Types for Process Systems

In industries where hygiene is paramount, such as dairy, food, pharmaceuticals, and biotechnology, the choice of union types for process systems is of utmost importance.

These unions facilitate the seamless connection of various components within piping systems while ensuring cleanliness, sterility, and ease of maintenance. In this comprehensive guide, we delve into six commonly used hygienic union types, their unique characteristics, applications, and advantages.

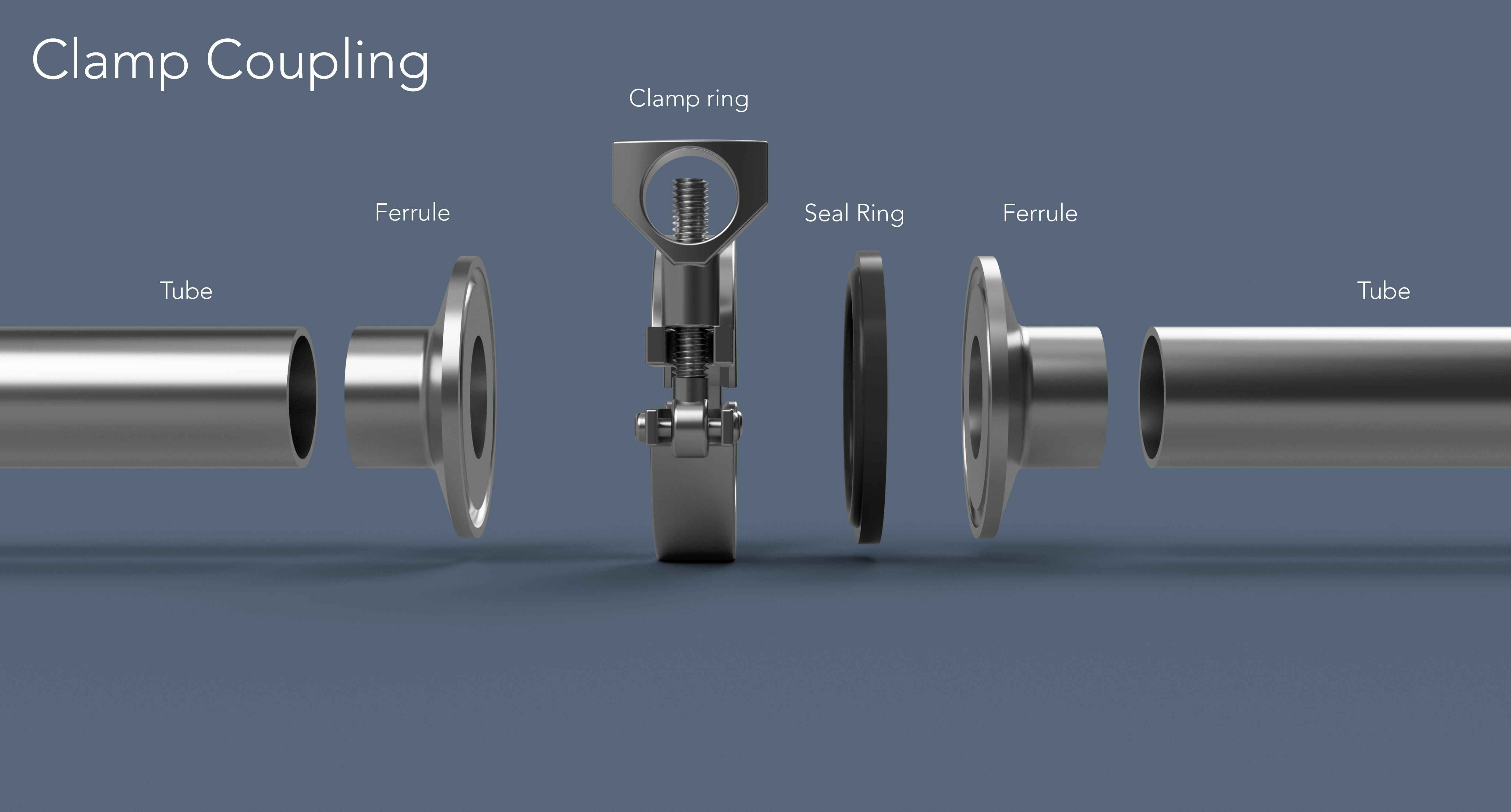

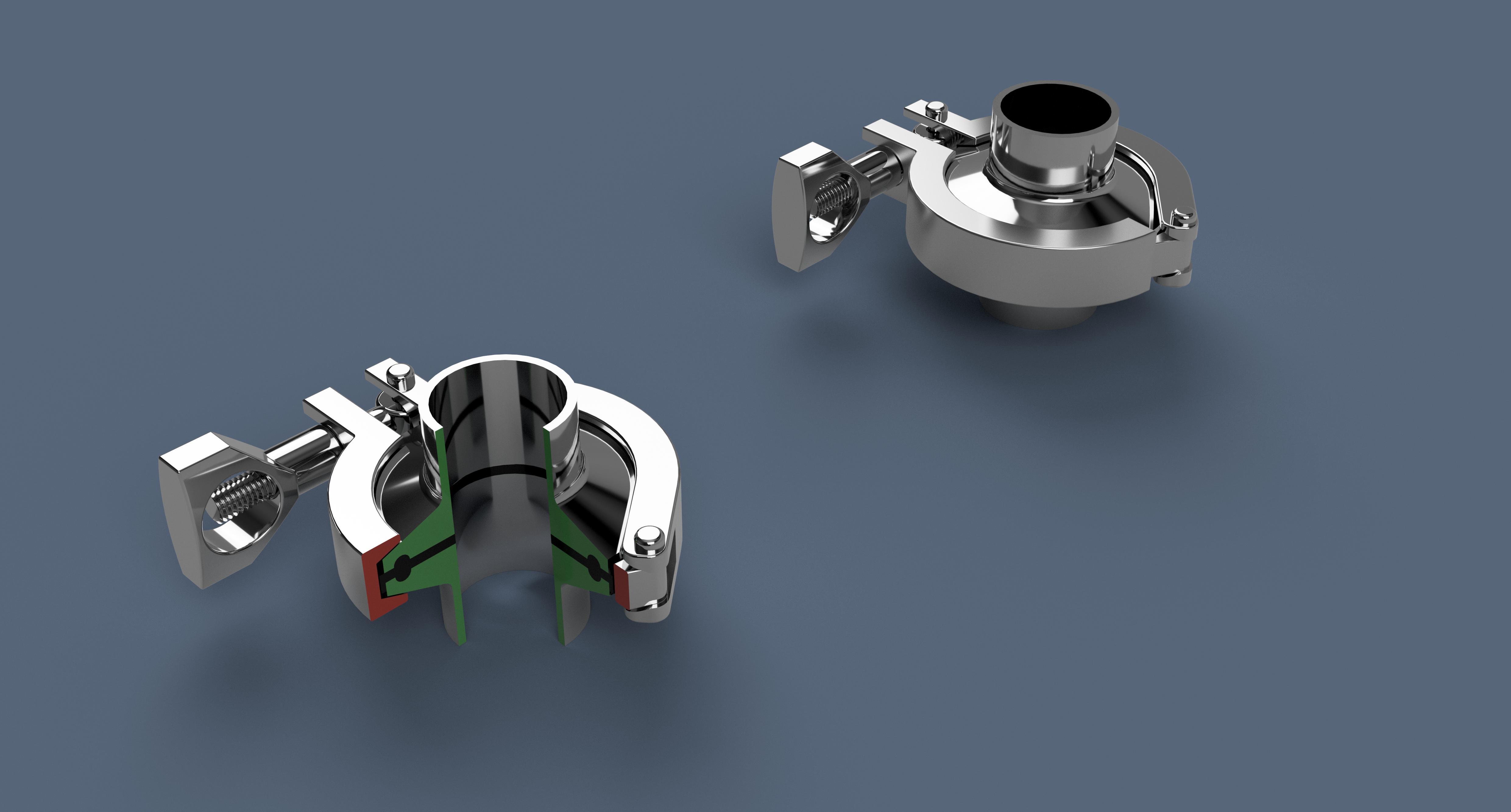

1. (Tri) Clamp Couplings

Tri clamp connections, hailed in various circles as tri clover or tri ferrule connections, stand as stalwarts in the realm of hygienic piping systems worldwide.

Their ubiquity owes much to their reputation for simplicity, reliability, and user-friendliness, which has solidified their status as go-to solutions for engineers and industry professionals alike.

At their core, tri clamp connections boast a straightforward composition comprising two identical ferrules, a hinged clamp, and a seal ring. This minimalist design belies their formidable performance capabilities and underscores their efficiency in facilitating hygienic connections.

A hallmark feature of tri clamp connections lies in their remarkable ease of assembly and disassembly, a trait that sets them apart in the realm of industrial fittings.

Unlike other connection methods that necessitate the use of specialized tools, tri clamp connections can be swiftly manipulated by hand, making them ideal candidates for applications demanding frequent cleaning or maintenance interventions

Their versatility knows no bounds, finding application across a diverse spectrum of industries, including dairy processing, breweries, pharmaceuticals, and cosmetics.

In environments where stringent hygiene standards reign supreme, tri clamp connections reign supreme, thanks to their ability to withstand pressures exceeding 10 bar (145 psi) at room temperature. This remarkable durability ensures their suitability for a wide array of hygienic process systems, providing engineers and operators with peace of mind regarding system integrity and reliability.

In essence, tri clamp connections embody the perfect fusion of form and function, offering unparalleled convenience without compromising on performance. As industries continue to prioritize cleanliness, efficiency, and reliability, tri clamp connections are poised to remain indispensable fixtures in the ever-evolving landscape of hygienic piping systems.

Available for

- DIN 11850

- EN 10357

- ASME-BPE

- BS 4825

- ISO 2037

- ISO 1127

Industries

- Dairy

- Breweries

- Cosmetics

- Chemicals

- Food & beverage

- Pharmacy

- Biotech

Clamp coupling parts

- Two identical ferrules

- A hinged clamp ring

- A seal ring

Advantages

- Ease of Assembly and Disassembly. Tri clamp connections are known for their simplicity and ease of use. They can be quickly assembled and disassembled without the need for specialized tools, making maintenance and cleaning operations more efficient compared to other types of unions.

- Good Interchangeability. Tri clamp connections feature identical ferrules, allowing for interchangeability between components. This interchangeability simplifies inventory management and reduces the need for specific matching components, leading to cost savings and greater flexibility in system design and maintenance.

- Wide Compatibility. Tri clamp connections are compatible with various tube standards, including DIN 11850, ASME BPE, BS 4825-1, ISO 2037, and ISO 1127. This wide compatibility ensures that they can be used in a diverse range of hygienic process systems across different industries without requiring significant modifications.

Disadvantages

- Limited Pressure Rating. Tri clamp connections typically have a lower pressure rating compared to other types of unions, such as flanged connections. While they can withstand pressures exceeding 10 bar (145 psi) at room temperature, they may not be suitable for applications requiring higher pressures without additional reinforcement.

- Sealing Performance. The sealing performance of tri clamp connections may be affected by factors such as surface finish and gasket material. Achieving a reliable seal may require careful attention to surface preparation and gasket selection, especially in applications where tight seals are critical to prevent leakage or contamination.

- Cost of Components. While tri clamp connections offer simplicity and ease of maintenance, the cost of individual components, such as ferrules, clamps, and gaskets, can add up, particularly for large-scale installations. Additionally, the need for specialized components, such as high-temperature or chemical-resistant gaskets, may further increase the overall cost of the system.

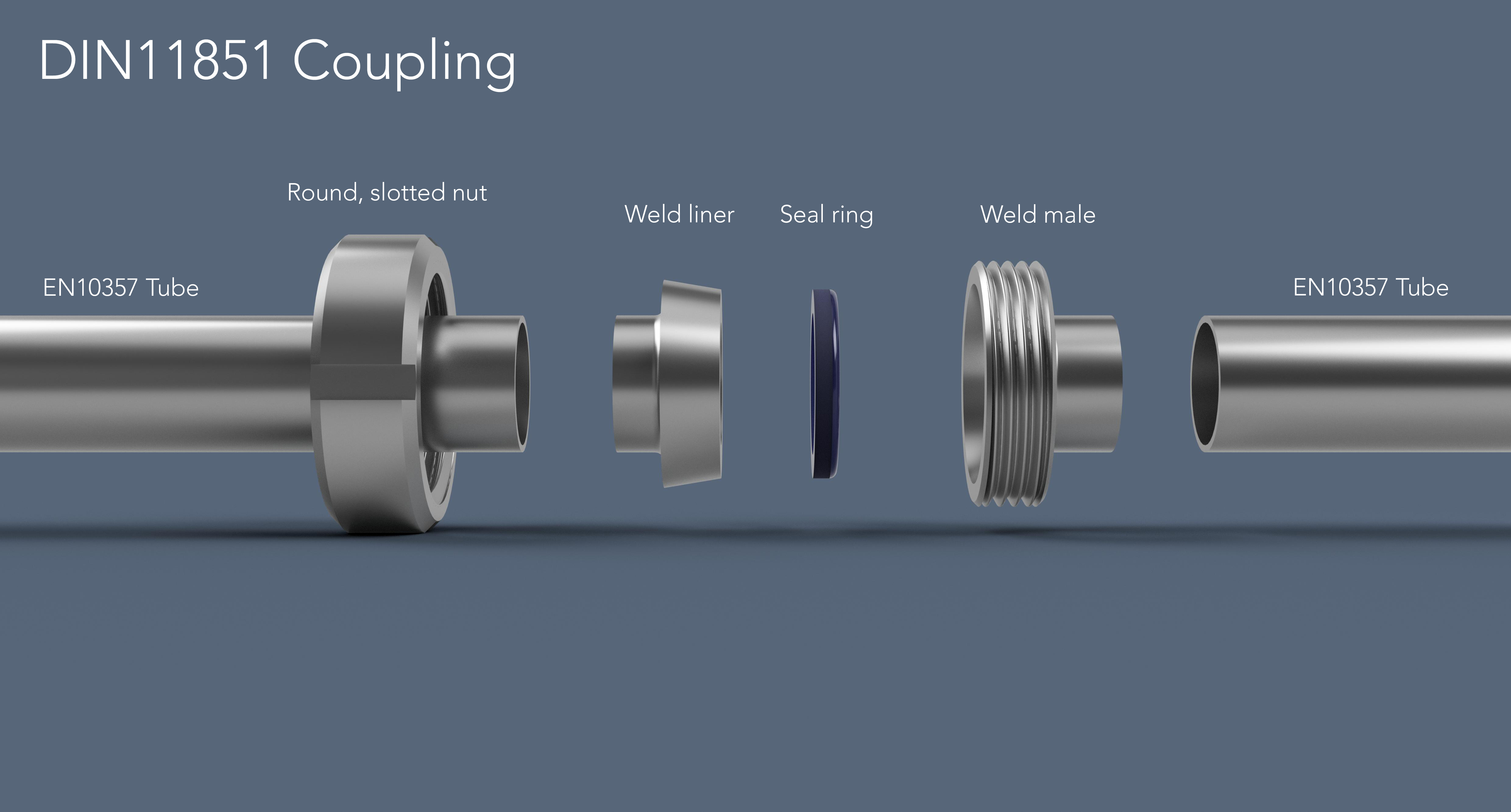

2. DIN11851 Couplings

DIN 11851 unions, affectionately known as dairy unions or milk couplings, stand as pillars of the dairy industry and find widespread adoption across various food processing applications, particularly in the vibrant landscape of Western Europe. Their reputation for reliability and performance has solidified their position as indispensable components in hygienic systems.

Comprising four essential components—a male threaded part, a liner, a round slotted nut, and a D-section seal—DIN 11851 unions exemplify simplicity without compromising on functionality. The wetted parts, crafted from high-quality 316L stainless steel, ensure optimal hygiene standards, while the accompanying nuts, typically made from grade 304 stainless steel, contribute to the unions' durability and longevity.

Engineered with ease of maintenance in mind, DIN 11851 unions offer a seamless balance between performance and convenience. Their design facilitates effortless assembly and disassembly, making them ideal candidates for applications necessitating frequent cleaning and maintenance interventions. Whether in dairy processing facilities, breweries, cosmetics manufacturing plants, chemical processing units, or pharmaceutical laboratories, DIN 11851 unions find their rightful place, providing reliable connections and ensuring operational efficiency.

Aligned with the DIN 11850 tube standard, these unions adhere to stringent quality specifications, further solidifying their reputation for excellence. Their versatility knows no bounds, catering to the diverse needs of industries where hygiene is paramount. As industries continue to prioritize cleanliness, reliability, and efficiency, DIN 11851 unions are poised to remain steadfast companions, supporting the seamless operation of hygienic systems and driving innovation in food processing and beyond.

Industries

- Dairy

- Breweries

- Cosmetics

- Chemicals

- Food & beverage

- Pharmacy

- Biotech

DIN 11851 coupling parts

- A male threaded part

- A liner

- A round slotted nut

- A D-shaped seal

Advantages

- High Pressure Rating. DIN 11851 unions are known for their robust construction and high-pressure rating, making them suitable for applications where elevated pressures are encountered. With a sturdy design and reliable sealing mechanism, DIN 11851 unions can withstand higher pressures compared to some other types of unions, providing added safety and durability in demanding environments.

- Wide Industry Acceptance. DIN 11851 unions are widely accepted and standardized within the dairy industry and other food processing sectors, particularly in Western Europe. Their widespread adoption ensures compatibility with existing equipment and facilitates interchangeability between components, reducing the complexity of system integration and maintenance.

- Diverse Applications. DIN 11851 unions are versatile and can be used in various industries beyond dairy processing, including breweries, cosmetics, chemicals, pharmaceuticals, and biotechnology. Their adaptability to different process requirements and tube standards makes them a preferred choice for a wide range of hygienic applications.

Disadvantages

- Complexity of Assembly. Compared to some other types of unions, such as tri clamp connections, DIN 11851 unions may require more time and effort for assembly and disassembly. The presence of multiple components, including a liner, nut, and seal, may increase the complexity of the installation process, particularly in applications where frequent maintenance is required.

- Limited Interchangeability. While DIN 11851 unions offer compatibility within the same standard, they may not be interchangeable with unions from other standards or manufacturers. This lack of interchangeability can pose challenges in situations where components need to be replaced or upgraded, potentially leading to compatibility issues and increased downtime.

- Cost Considerations. The initial cost of DIN 11851 unions and their components may be higher compared to some other types of unions, such as RJT or SMS unions. Additionally, the need for specific materials, such as 316L stainless steel for wetted parts, and adherence to strict manufacturing standards may contribute to higher procurement costs, particularly for large-scale installations.

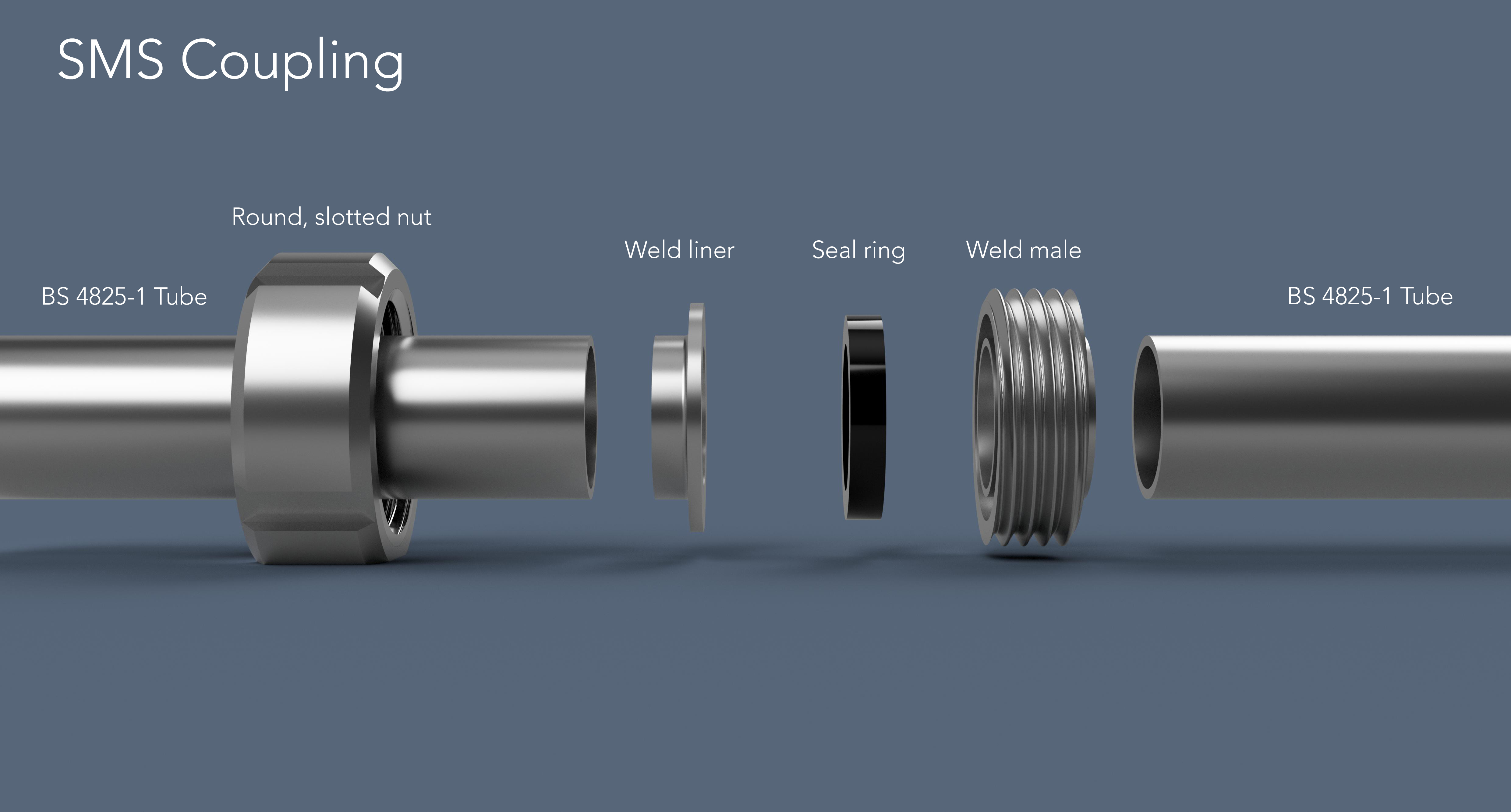

3. SMS Couplings

- SMS (Swedish Manufacturing Standard) unions stand as notable counterparts to DIN 11851 unions, boasting similarities in their application domains while showcasing distinctive features in their design and sealing mechanisms.

- Unlike DIN 11851 unions, SMS unions exhibit a flat face female part and a turned-up seal on the male part, diverging from the conical face and D-shaped seal configuration of their DIN counterparts. This nuanced difference contributes to the unique performance characteristics of SMS unions, distinguishing them in the realm of hygienic connections.

- Furthermore, SMS unions are characterized by a lower working pressure, typically hovering around 6 bar (87 psi). While this may denote a limitation in certain high-pressure applications, it underscores the specific niche in which SMS unions excel, offering reliable performance within their designated pressure range.

- Despite these disparities, SMS unions find themselves traversing similar industrial landscapes as DIN 11851 unions, catering to the needs of sectors such as dairy processing, breweries, cosmetics manufacturing, chemicals, and pharmaceuticals. Their widespread adoption in regions where DIN standards hold sway underscores their versatility and compatibility with existing infrastructure.

- Aligned with tube standards such as BS 4825 and ISO 2037, SMS unions seamlessly integrate into hygienic systems, offering engineers and operators a trusted solution for their connectivity needs. Whether in the sterile environments of pharmaceutical laboratories or the bustling production floors of breweries, SMS unions play a vital role in maintaining hygienic integrity and operational efficiency.

Avaialble for

- BS 4825

- ISO 2037

Industries

- Dairy

- Breweries

- Cosmetics

- Chemicals

- Food & beverage

- Pharmacy

- Biotech

SMS coupling parts

- A male threaded part

- A liner

- A round slotted nut

- A square shaped seal

Advantages

- Cost-Effectiveness. SMS (Swedish Manufacturing Standard) unions are often more cost-effective compared to some other types of unions, such as DIN 11851 unions or flanged connections. Their simpler design and manufacturing process contribute to lower production costs, making them an attractive option for budget-conscious applications without compromising on quality.

- Availability in Similar Regions as the other union types. SMS unions are prevalent in regions where DIN standards, such as DIN 11850, are commonly used. This ensures compatibility with existing equipment and facilitates ease of sourcing components from local suppliers. The familiarity and acceptance of SMS unions within these regions simplify installation, maintenance, and system integration processes.

- Flat Face Design. Unlike some other unions that feature conical face designs, SMS unions have a flat face female part, which can offer advantages in certain applications. The flat face design provides uniform sealing contact and may be preferred in situations where precise sealing performance is critical to prevent leakage or contamination.

Disadvantages

- Lower Pressure Rating. SMS unions typically have a lower working pressure compared to unions such as DIN 11851 or flanged connections. With a working pressure of around 6 bar (87 psi), SMS unions may not be suitable for applications that require higher pressure capabilities without additional reinforcement or support.

- Limited Compatibility. While SMS unions are widely accepted in regions where DIN standards are prevalent, they may not be as compatible or interchangeable with unions from other standards or manufacturers. This limited compatibility can pose challenges in situations where components need to be replaced or upgraded, potentially leading to compatibility issues and increased downtime.

- Sealing Mechanism. The sealing mechanism of SMS unions, which typically utilizes square-shaped seals, may differ from other types of unions. While effective when properly installed, square-shaped seals may have specific requirements for alignment and compression to ensure reliable sealing performance. Improper installation or maintenance practices could compromise the integrity of the seal, leading to leakage or contamination issues.

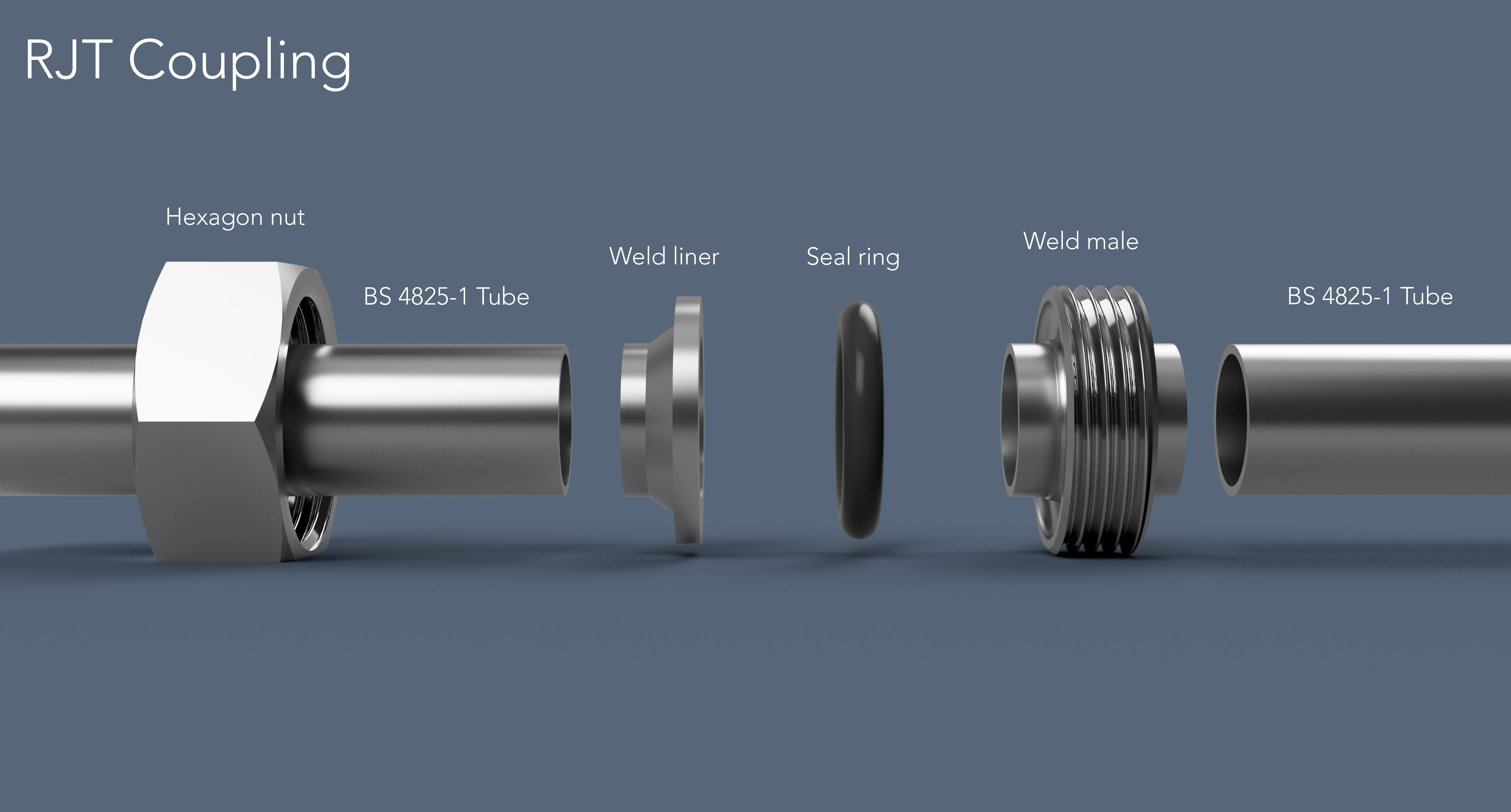

4. RJT Couplings

RJT (Ring Joint Type) unions have established themselves as indispensable components in hygienic systems, not only in the United Kingdom but also across the globe. Their widespread usage underscores their effectiveness in facilitating hygienic connections in various industries.

These unions boast a straightforward yet robust design, consisting of essential components such as a male threaded part, a pressed liner, a hexagon nut, and an O-ring seal. This simplicity belies their significance in ensuring the integrity and efficiency of hygienic systems.

One of the key attributes of RJT unions is their reputation for reliability. Engineers and maintenance professionals rely on RJT unions to deliver consistent performance, minimizing the risk of leaks or contamination. The pressed liner and O-ring seal form a tight and dependable seal, enhancing system reliability and preventing costly downtime.

Moreover, the ease of maintenance associated with RJT unions further contributes to their appeal. Maintenance tasks such as assembly, disassembly, and component replacement can be accomplished with minimal effort and time, reducing operational disruptions and optimizing productivity.

Avaialble for

- BS 4825

- ISO 2037

Industries

- Dairy

- Breweries

- Cosmetics

- Chemicals

- Food & beverage

- Pharmacy

- Biotech

RJT coupling parts

- A male threaded part

- A liner

- A hexagon nut

- An O- shaped seal

Advantages

- Simplicity and Reliability: RJT unions are known for their simple and reliable design, consisting of a male threaded part, a pressed liner, a hexagon nut, and an O-ring seal. This straightforward construction makes them easy to install, maintain, and disassemble, reducing the likelihood of errors or complications during operation.

- Wide Industry Acceptance: RJT unions are widely accepted and utilized in the United Kingdom and other countries for hygienic connections. Their widespread adoption ensures compatibility with existing equipment and facilitates ease of sourcing components from local suppliers. This familiarity with RJT unions simplifies installation, maintenance, and system integration processes.

- Cost-Effectiveness: Compared to some other types of unions, such as DIN 11851 unions or flanged connections, RJT unions are often more cost-effective. Their simpler design and manufacturing process contribute to lower production costs, making them an attractive option for applications where budget considerations are paramount.

Disadvantages

-

Limited Pressure Rating: RJT unions may have a lower working pressure compared to unions such as DIN 11851 or flanged connections. While suitable for many applications, they may not be appropriate for high-pressure systems without additional reinforcement or support.

-

Limited Interchangeability: RJT unions may not be as interchangeable with unions from other standards or manufacturers compared to some more standardized types of unions, such as tri clamp connections or DIN 11851 unions. This lack of interchangeability can limit flexibility in system design and may require specific components to be sourced from the original manufacturer, potentially leading to longer lead times and higher costs for replacements or upgrades.

-

Complexity of Assembly: While RJT unions are generally simpler compared to some other types of unions, such as flanged connections, they still involve multiple components and threaded connections. This complexity can result in longer assembly times and may require more skill to ensure proper alignment and sealing, particularly in applications where precision is critical.

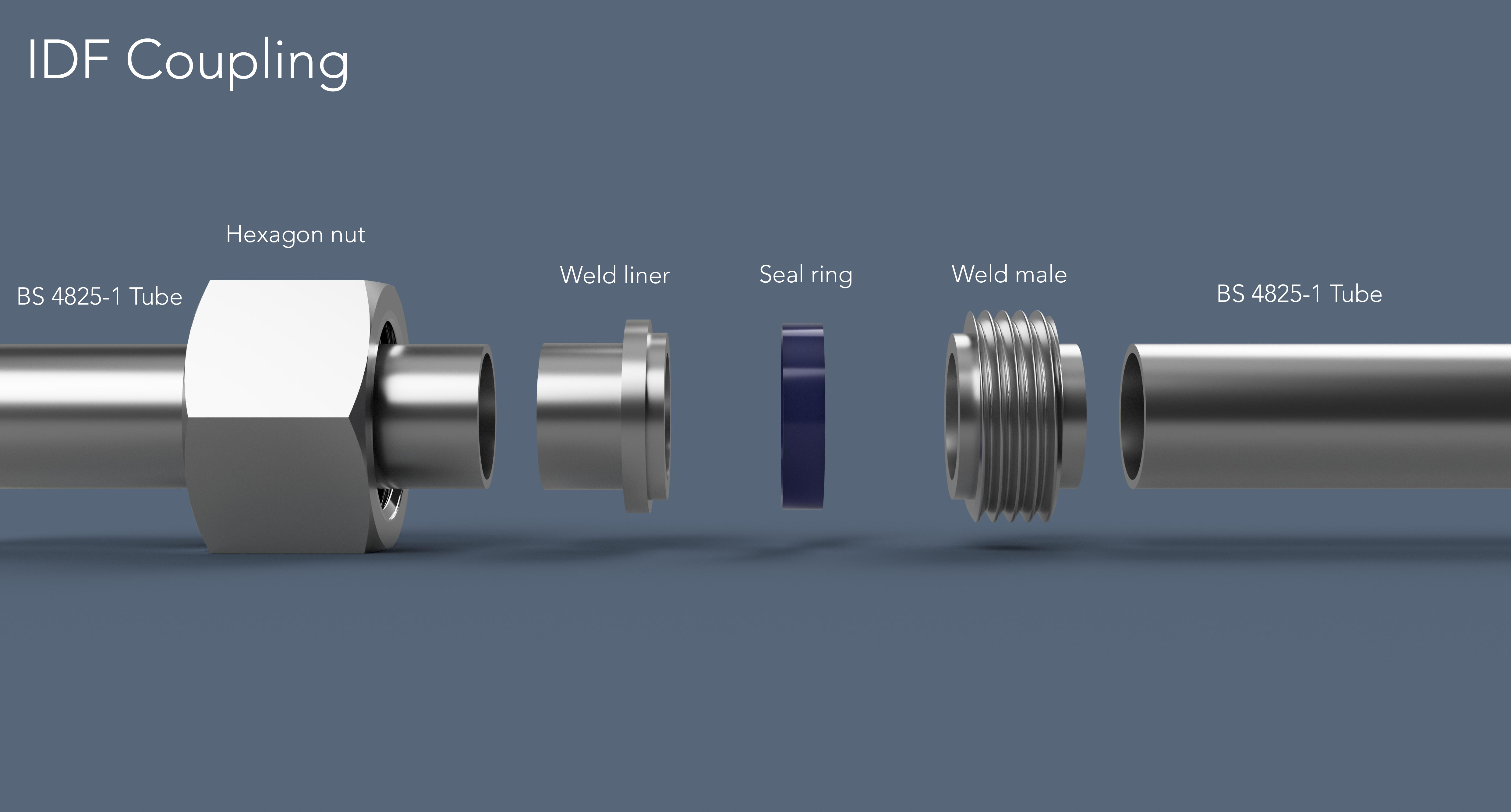

5. IDF Couplings

IDF (International Dairy Federation) unions, while less prevalent than some of their counterparts, stand as stalwart solutions within the realm of hygienic connections, offering a dependable option tailored to specific applications.

Designed to meet the exacting hygiene standards demanded by industries such as dairy processing, breweries, and pharmaceuticals, IDF unions embody a commitment to precision and reliability, ensuring the integrity of critical process systems.

Comprising essential components such as a male threaded part, a liner, a nut, and a seal, IDF unions adhere to stringent tube standards like BS 4825, underscoring their dedication to quality and compliance. Each component is meticulously crafted to deliver optimal performance, providing engineers and operators with confidence in their connectivity solutions.

Despite their relative rarity compared to more widely used unions, IDF unions fill a crucial niche in industries where uncompromising hygiene is non-negotiable. Their precision-engineered design and adherence to industry standards make them a preferred choice for applications where reliability and accuracy are paramount.

In dairy processing facilities, breweries, and pharmaceutical laboratories, IDF unions serve as trusted allies, facilitating seamless connections while upholding the highest standards of hygiene and safety. Their specialized design and construction ensure compatibility with industry-specific requirements, making them indispensable components in critical process systems.

Avaialble for

- BS 4825

- ISO 2037

Industries

- Dairy

- Breweries

- Cosmetics

- Chemicals

- Food & beverage

- Pharmacy

- Biotech

IDF coupling parts

- A male threaded part

- A liner

- A hexagon nut

- A T-shaped seal

Advantages

- Specific Design for Hygienic Applications: IDF couplings are specifically designed to meet the stringent hygiene standards required in industries such as dairy processing, breweries, and pharmaceuticals. Their design is optimized for these applications, providing a reliable solution for critical process systems in these sectors.

- Precise and Reliable Connections: IDF couplings offer precise and reliable connections for critical process systems. Each component is carefully designed and manufactured to deliver optimal performance, allowing engineers and operators to trust in the integrity of their connections.

- Compliance with Industry Standards: IDF couplings comply with strict tube standards such as BS 4825, ensuring they meet the standards and regulations applicable in the industries where they are used. This compliance with standards contributes to the reliability and compatibility of IDF couplings in various applications.

Disadvantages

- Relative Rarity: Compared to some other couplings mentioned in the article, such as tri clamp or DIN 11851 couplings, IDF couplings may be less commonly available. This can lead to challenges in procurement and replacement of parts, especially in regions where they are less common.

- Less Wide Acceptance: IDF couplings may be less widely accepted than some other types of couplings, such as DIN 11851 unions, which are widespread in the dairy industry and other sectors. This can result in limitations in integrating IDF couplings into existing systems or collaborating with other equipment and components.

- Limited Information Sources and Expertise: Due to their relative rarity, information sources and expertise related to IDF couplings may be less widespread than for more common couplings. This can lead to challenges in the design, installation, and maintenance of IDF couplings, especially for engineers and operators who are less familiar with this specific type of coupling.

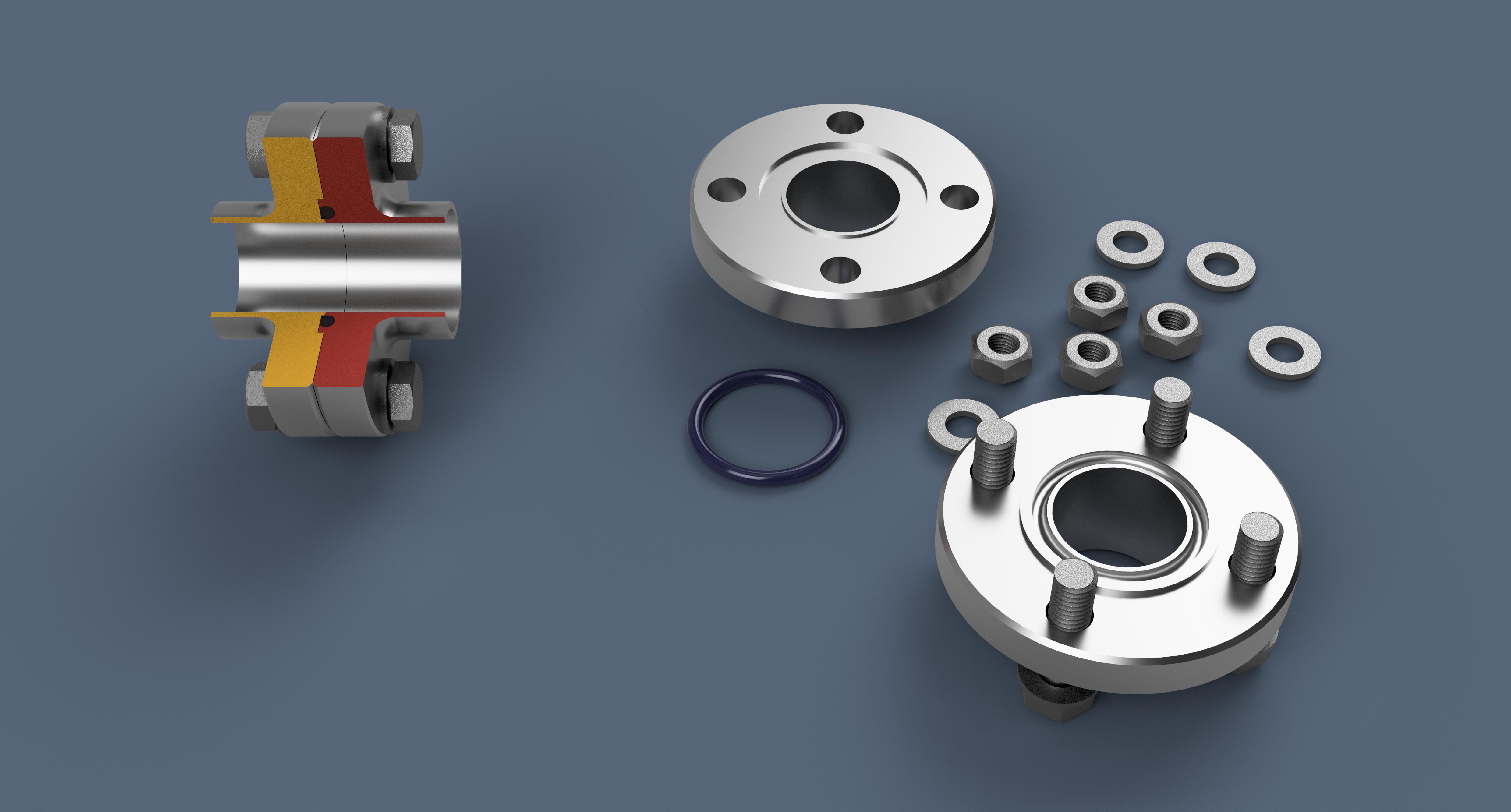

6. Flange Connections

For applications demanding higher pressures or intricate configurations, flanged connections stand out as an indispensable solution, renowned for their robustness and versatility. Adhering to rigorous standards such as DIN 11853, these connections epitomize stability and durability, even in the harshest and most demanding environments encountered in various industries.

Flanged connections boast a design tailored to withstand elevated pressures and accommodate specialized configurations with ease. Their construction incorporates sturdy flanges and bolts, ensuring a secure and leak-proof seal under significant pressure loads. This robustness makes them particularly well-suited for applications where system integrity is non-negotiable, such as in chemical processing plants, oil refineries, and power generation facilities.

Moreover, the adherence to standards like DIN 11853 underscores the reliability and consistency of flanged connections across different applications and industries. These standards dictate precise specifications for flange dimensions, materials, and assembly procedures, ensuring uniformity and interoperability in diverse environments. Engineers and operators can thus rely on flanged connections to deliver consistent performance and longevity, mitigating the risk of costly downtime and maintenance issues.

Furthermore, flanged connections offer versatility beyond their resilience to high pressures. Their design allows for easy adaptation to various system configurations, including the integration of valves, pumps, and other components. This flexibility enables engineers to design complex process systems tailored to specific operational requirements, enhancing efficiency and productivity in industrial settings.

Related articles

-

Standards for Hygienic Fittings in Dairy & Food Production

-

Designing hygienic process systems: The DIN-EN standards

-

Designing hygienic process systems : The BS4825 standards

-

Designing hygienic process systems: About stainless steel

-

Designing hygienic process systems: Tri-clamp ferrule dimensions

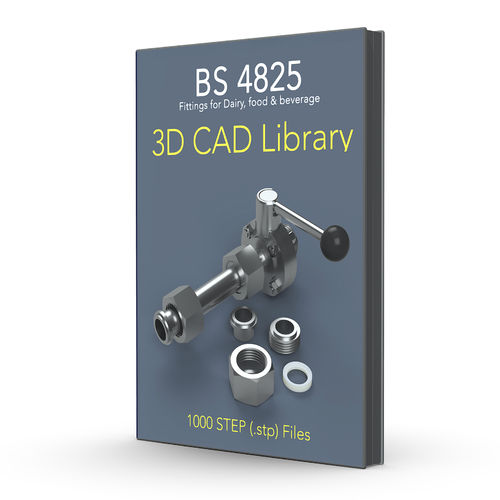

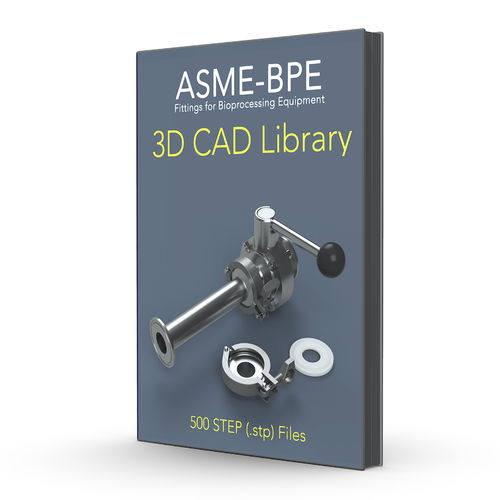

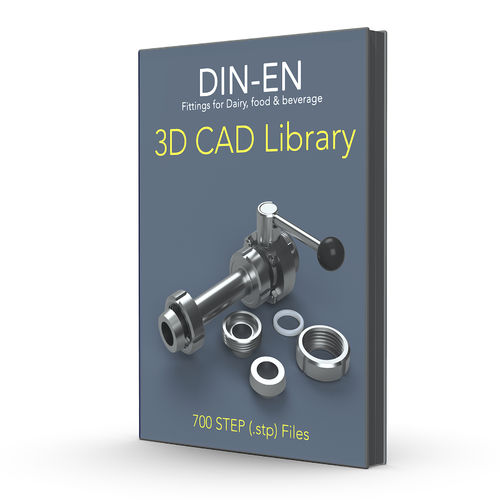

Check out our 3D CAD Libraries

BS4825 Hygienic Fittings and Valves - 1000 STEP FilesDownload this complete 3D CAD library (2 zip files) and get access to 1000 premium quality hygienic BS4825 fittings! (in STEP file format). |

ASME-BPE Hygienic Fittings and Valves - 500 STEP FilesDownload this complete 3D CAD library (1 zip file) and get access to 500 premium quality hygienic ASME-BPE fittings! (in STEP file format). |

DIN-EN Hygienic Fittings and Valves - 700 STEP FilesDownload this complete 3D CAD library (1 zip file) and get access to 700 premium quality hygienic DIN-EN fittings! (in STEP file format). |