Premium Quality 3D CAD Files for Your Engineering Projects

3D CAD Files Collections Info for 3D CAD Engineers DIN-EN Hygienic

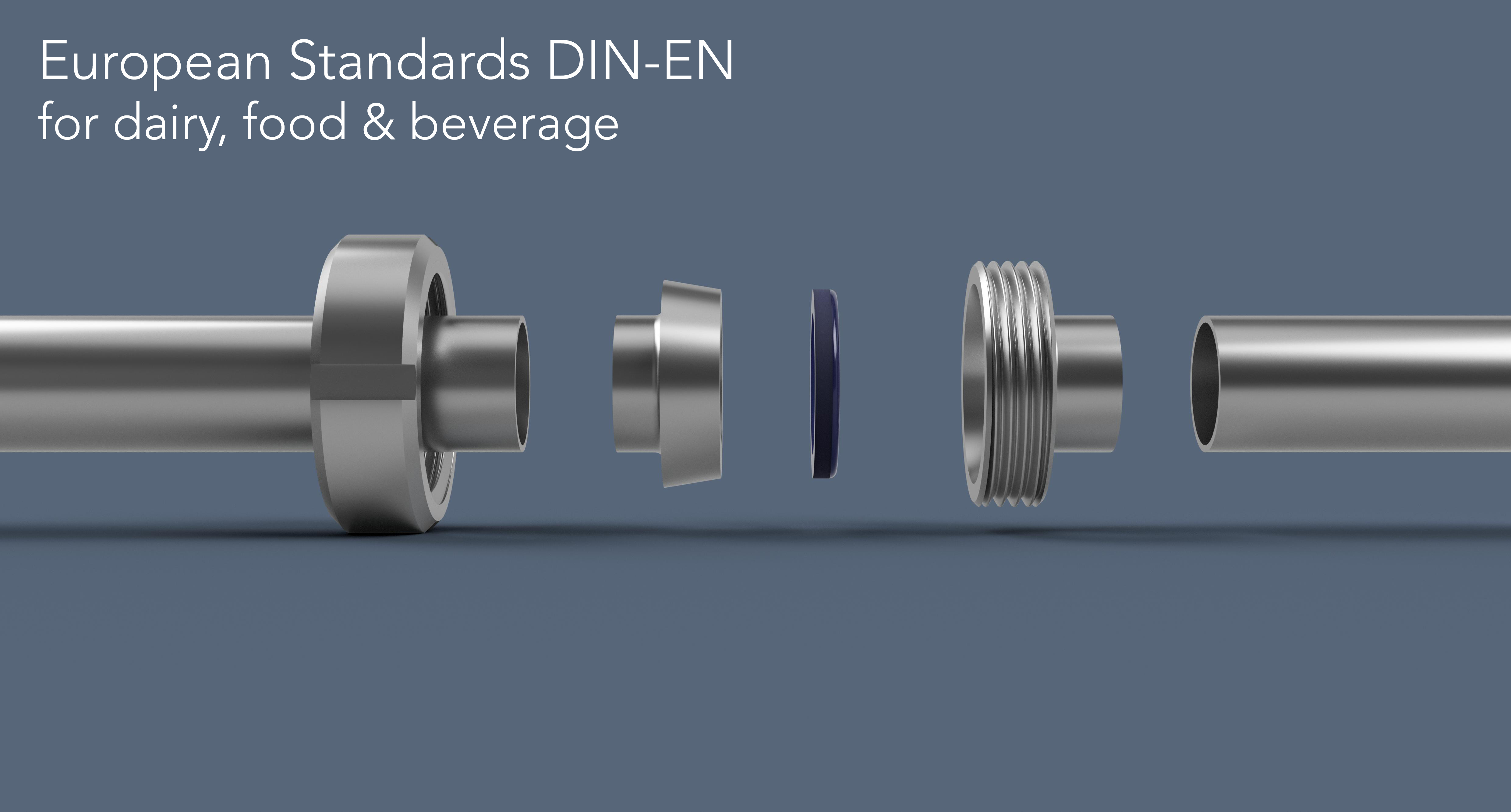

Designing hygienic process systems: The DIN-EN standards

DIN-EN 10357: The European standard for hygienic tubes

General information about the DIN-EN 10357 standard

Since 2014 the DIN EN 10357 series A and B have been the new standards for hygienic tubes; also known as “food tubes” replacing their predecessors DIN 11850 R1 and R2.

DIN EN 10357 series A and B are originally from Germany, however, they are regularly used all over the world such as Europe, Australia and the Middle East, just to mention a few.

These tubes are mainly used in the food & beverage, pharmaceutical and chemical industry and are also often installed in hospitals.

In order to reach the DIN EN 10357 standards’, the tubes has to meet certain requirements regarding their materials, surface treatments, dimensions and tolerances which will ensure a consistent level of quality.

Due to this standardization, these tubes are interchangeable with one another no matter where you are in the world or which supplier you bought the parts from.

DIN-EN 10357, the materials:

In hygienic production lines, fittings and valves are always made of stainless steel.

The types of stainless steel used for EN 10357 A/B tubes are the following:

304 Stainless steel(AISI 304) |

High resistance against rust but susceptible to corrosion from chloride solutions. |

316 Stainless steel(AISI 316) |

High resistance against rust and good resistance against chlorides and other industrial solvents. |

In terms of material composition these steels are not special, thus, can be produced worldwide with no problem. There are alternate versions of these kind of steels namely 304L and 316L which have better welding properties.

Generally 316 stainless steel is a bit more expensive, but that is not always the case especially in smaller, commonly used diameters the price difference can be negligible.

Seal rings and gaskets come in a lot of materials, for instance, EPDM, Viton, PTFE and much more. In this case, it is critical to choose the right one since these materials have very different properties.

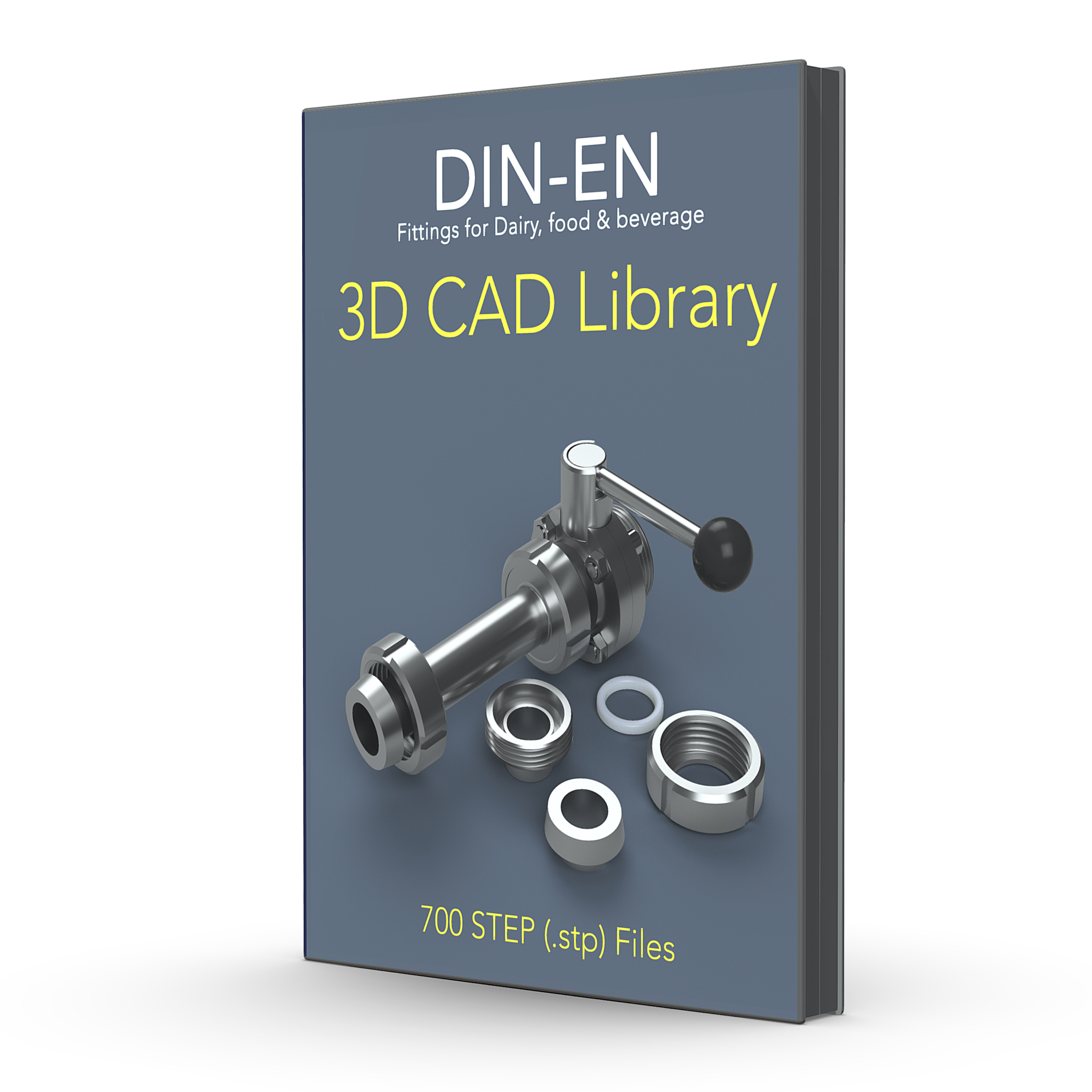

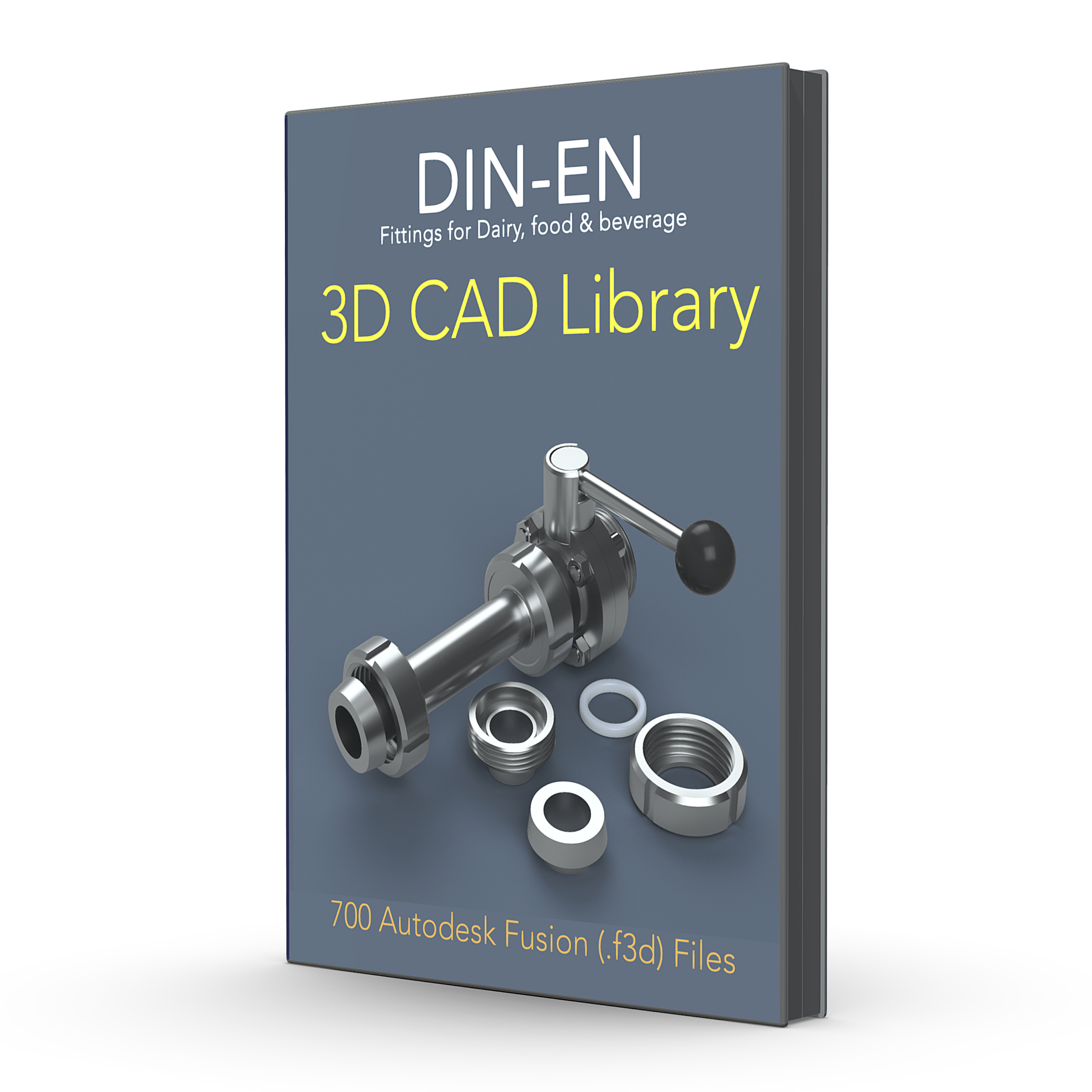

Check out our DIN-EN hygienic fittings 3D CAD files libraries |

|

|

|

|

STEP (.stp) files library |

Autodesk Fusion 360 .f3d files library |

Autodesk Inventor, solidworks, Catia, AutoCAD and more. |

Autodesk Fusion optimized |

EN-10357 Series A (DIN 11850 Range 2) tube sizes |

||

Size (DN) |

Outside diameter (mm). |

Thickness (mm). |

10 |

13 |

1,50 |

15 |

19 |

1,50 |

20 |

23 |

1,50 |

25 |

29 |

1,50 |

32 |

35 |

1,50 |

40 |

41 |

1,50 |

50 |

53 |

1,50 |

65 |

70 |

2,00 |

80 |

85 |

2,00 |

100 |

104 |

2,00 |

125 |

129 |

2,00 |

150 |

154 |

2,00 |

200 |

204 |

2,00 |

EN-10357 Series B (DIN 11850 Range 1) tube sizes |

||

Size (DN) |

Outside diameter (mm). |

Thickness (mm). |

10 |

12 |

1,00 |

15 |

18 |

1,00 |

20 |

22 |

1,00 |

25 |

28 |

1,00 |

32 |

34 |

1,00 |

40 |

40 |

1,00 |

50 |

52 |

1,00 |

Fittings for DIN EN 10357 series A tubes:

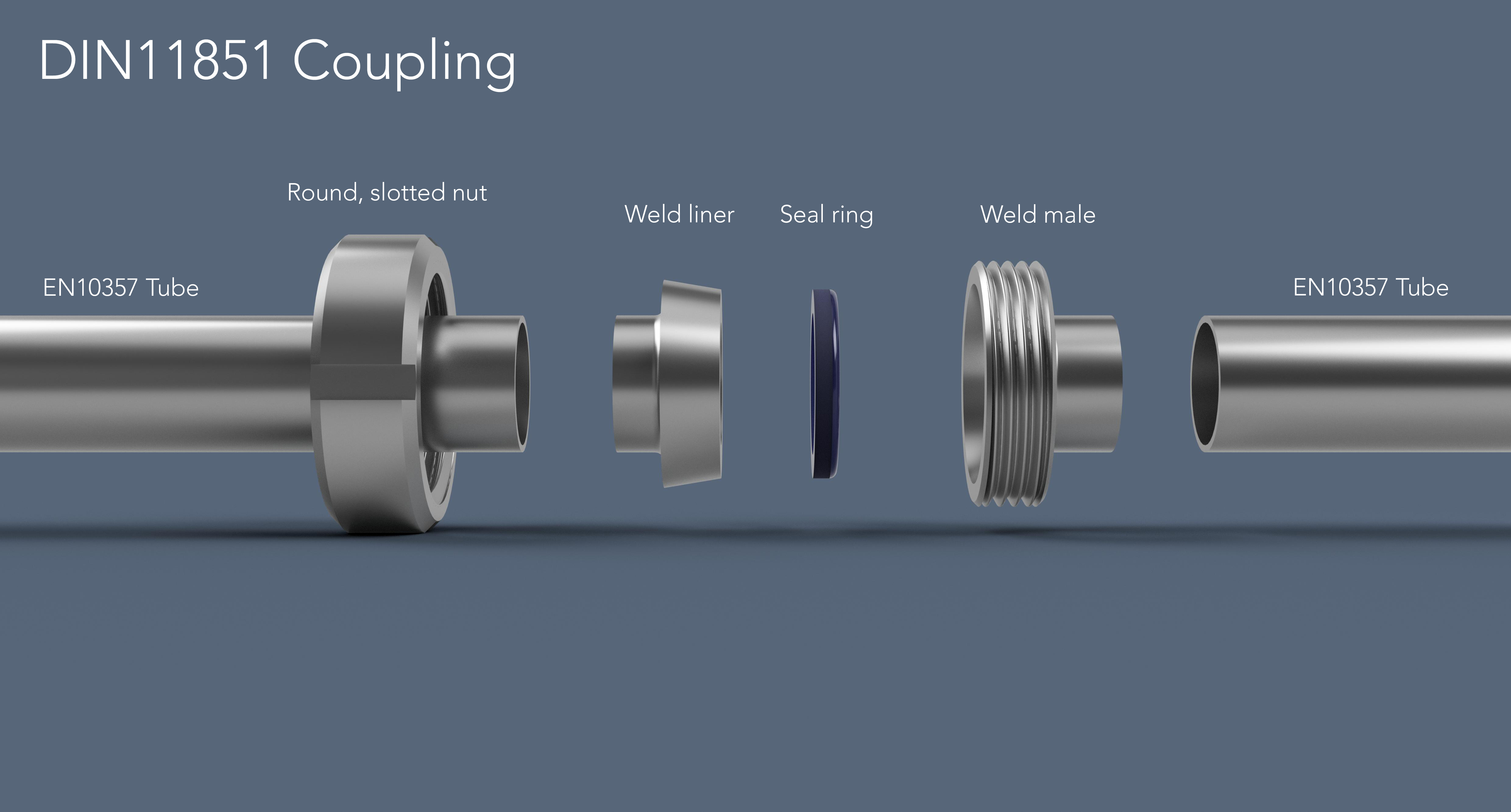

1. DIN 11851 Unions

DIN 11851 is a standard for a hygienic union consisting of four parts, which are fully compatible with EN 10357 series A tubes.

This type of union is used in product lines that require regular assembling and disassembling

You only one piece of tool: a spanner wrench.

The four different parts of a DIN 11851 connection:

1. A male threaded part

2. A conical shaped liner

3. A D-shaped seal ring

4. A round (slotted) nut

The working principle of DIN11851 couplings

By tightening the nut, the seal ring is clamped by the liner in a groove of the male part. This creates a very reliable, clean and fluid-tight connection.

2. DIN 11852 (EN 10374-A) weld fittings

Out of all the tube connection methods, the welded connection is the cheapest and the most reliable one.

The DIN11852 standard outlines the specifications for hygienic welded fittings, encompassing bends, T-pieces, and reducers. Originally embraced by EuroNorm standardization, the DIN-EN 10374-A standard has since succeeded the DIN11852 standard, a transition aimed at harmonizing European standards.

Despite this transition, numerous suppliers continue to provide these fittings under the DIN11852 standard designation. This perpetuation of the DIN11852 classification by suppliers may stem from factors such as existing inventory, market familiarity, or client demand. As such, while the DIN-EN 10374-A standard represents the latest harmonized standard, DIN11852 fittings persist within the market due to historical precedents and industry practices.

DIN11852, or DIN-EN 10374-A fittings are readily available in almost every country, usually in diameters up to DN150 and in both materials: AISI 304L and AISI 316L.

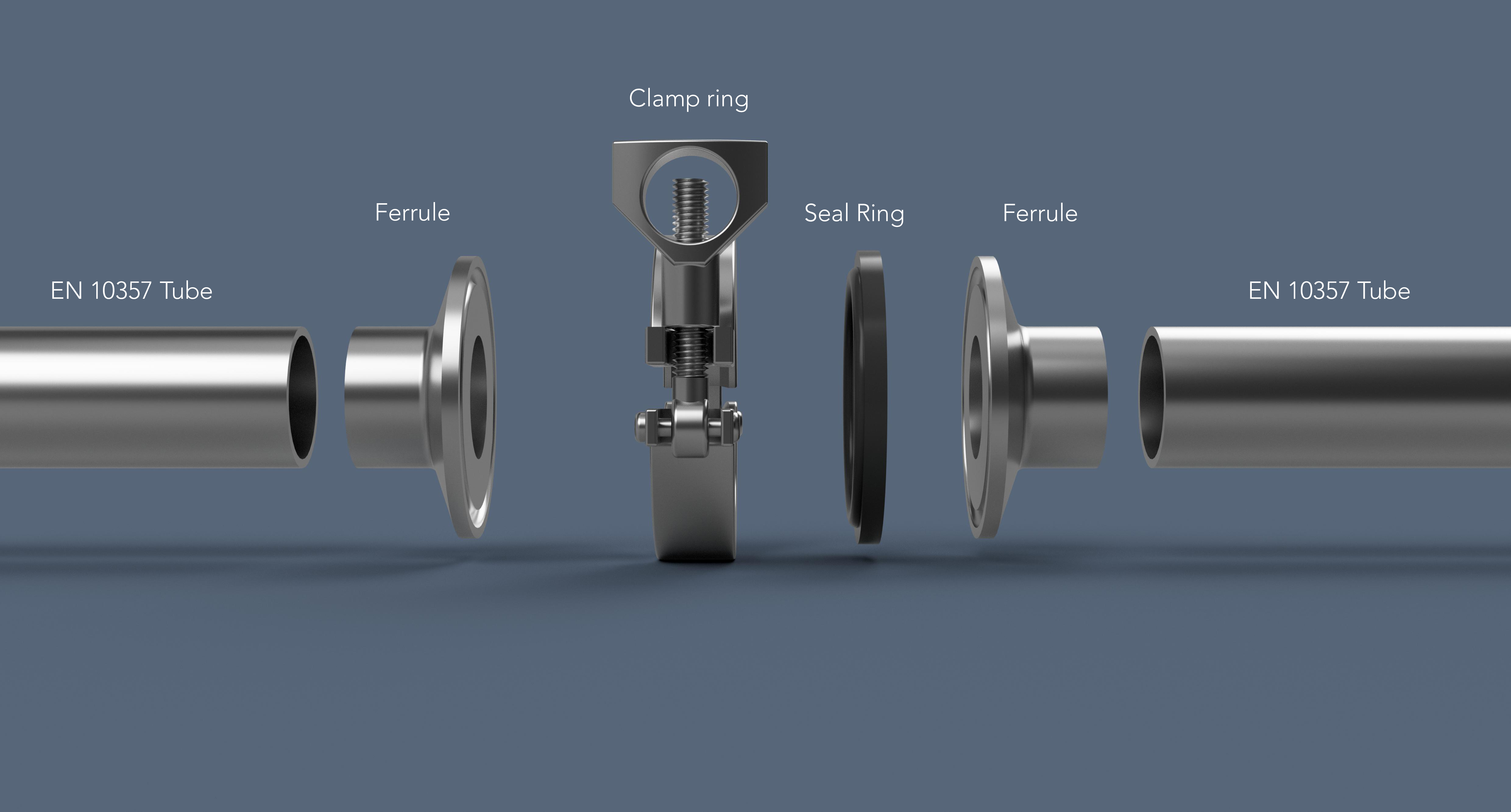

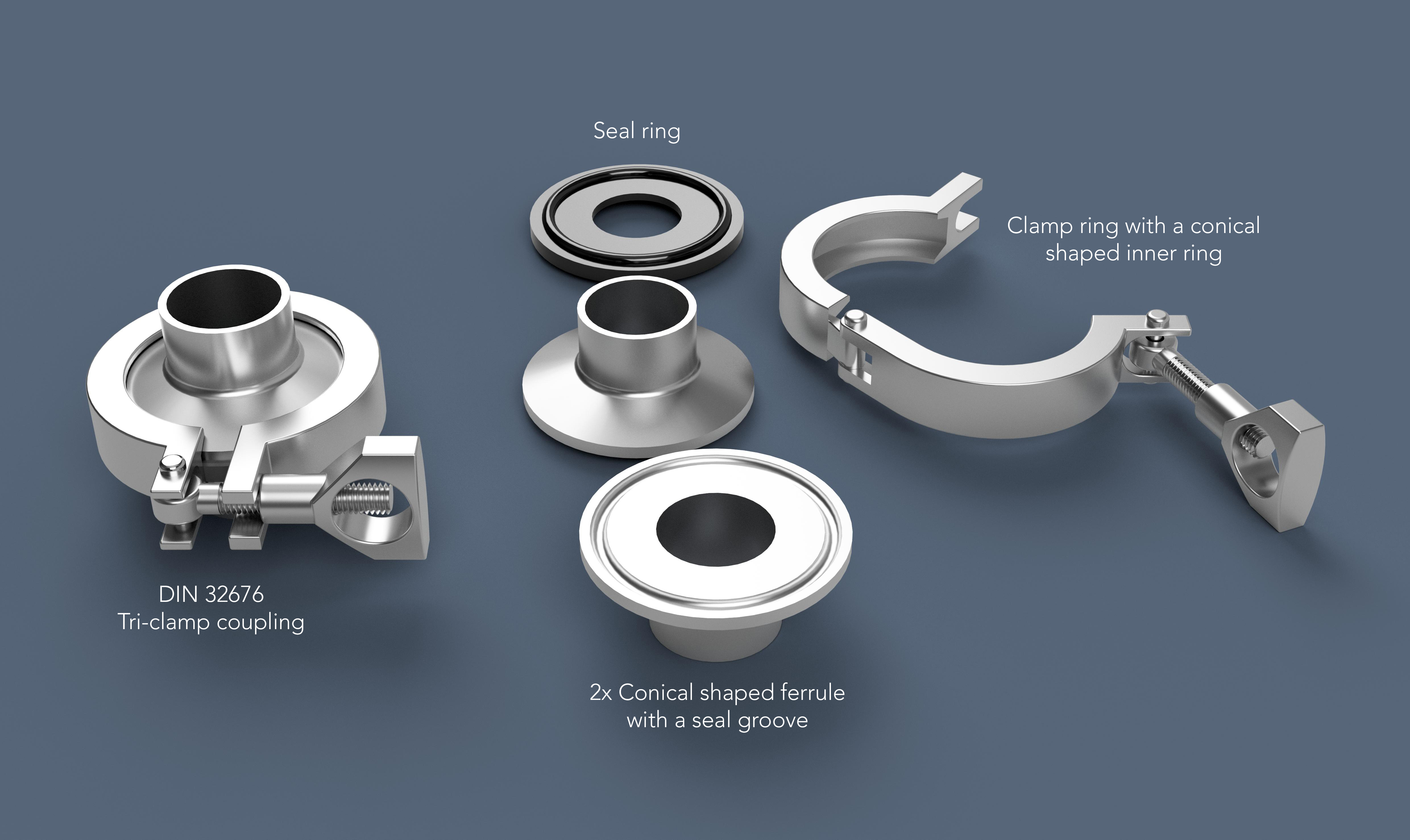

3. DIN 32676 tri clamp unions

Tri clamps union is used when a tubing system has to be assembled and disassembled very often and very quickly. Mostly there are no tools needed to tighten the connection, you can simply open or close the clamp ring by turning the butterfly nut. There are also clamp rings available with hexagonal nuts; then you need a wrench.

DIN 32676 tri-clamp fittings are a specific type of fittings that comply with the EN 10357 standard for hygienic process tubes. These fittings are widely used in the food, pharmaceutical, and chemical industries due to their hygienic design, easy installation, and reliable sealing.

Tri-clamp fittings provide a reliable and hygienic solution for connecting process piping in critical industries, meeting the stringent standards and requirements for food safety and product quality.

- Triple clamp attachment: These fittings are named for their use of a triple clamp attachment to ensure the connection between two pipes or between a pipe and a process component. This provides a secure and leak-proof connection.

- Sanitary design: DIN 32676 tri-clamp fittings are designed according to sanitary principles, with smooth surfaces and rounded corners to improve cleanability and minimize the risk of bacterial growth. This makes them ideal for applications where hygiene is critical.

- Material options: These fittings are typically manufactured from high-quality materials such as stainless steel (e.g., AISI 304 or AISI 316L), ensuring durability, corrosion resistance, and compatibility with a wide range of process media.

- Easy installation: The design of DIN 32676 tri-clamp fittings allows for quick and easy installation, saving time and costs during assembly and maintenance of piping systems.

The three different parts of a tri-clamp connection

1. Two identical conical shaped ferrules with a seal groove

2. A seal ring

3. A clamp ring with a conical shaped inner ring.

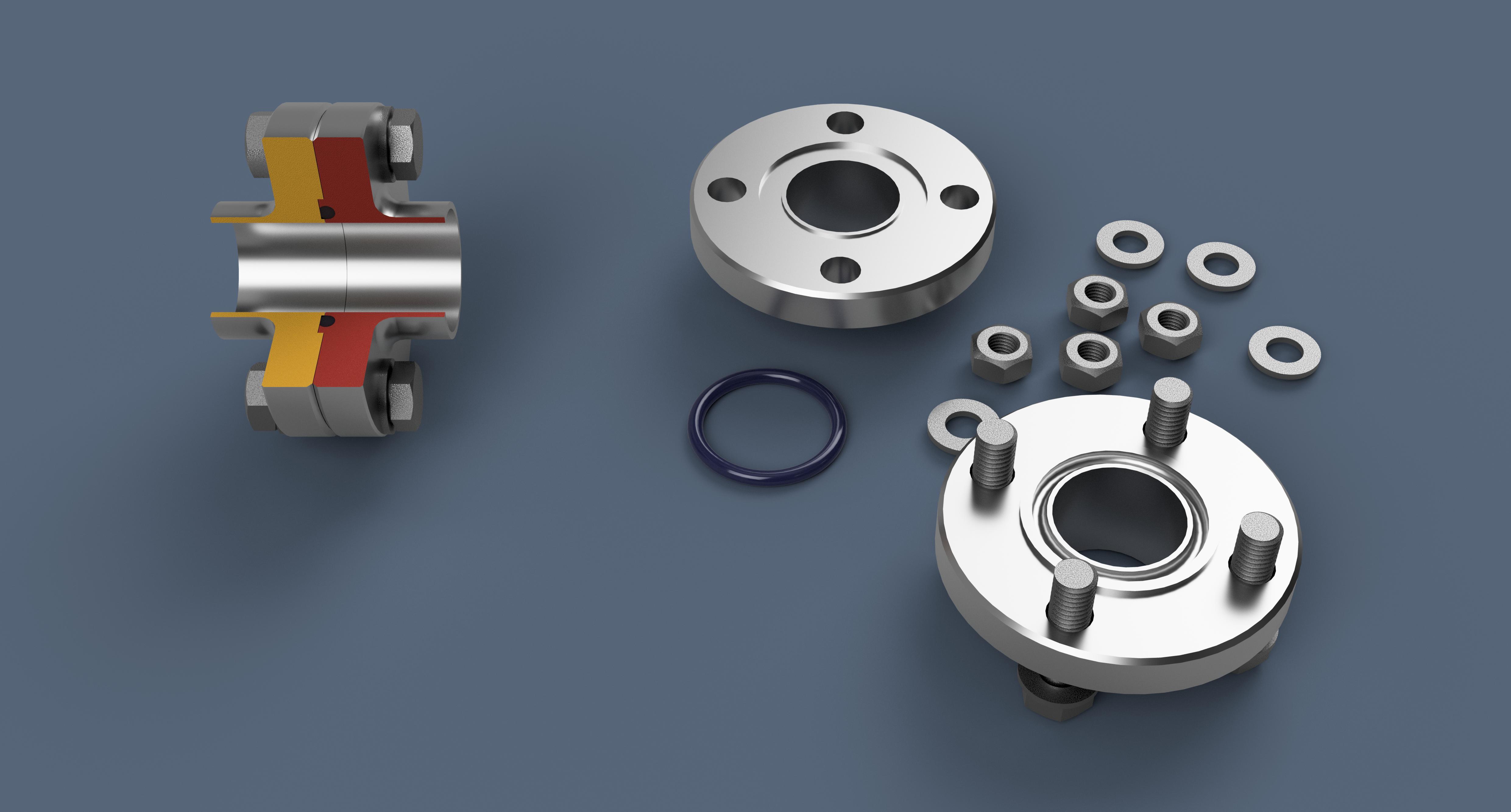

4. Flange connections

DIN 11853 flanges

A DIN11853 flange is a type of flange connection specified by the German standard DIN 11853. This standard outlines the design, dimensions, materials, and testing requirements for hygienic pipe connections with flanges used in industries such as food processing, pharmaceuticals, and biotechnology.

Key features

- Design: DIN11853 flanges are designed to provide a hygienic and secure connection between two piping components, such as pipes or fittings. The design may include variations such as flanges with flat sealing faces (Type 1), flanges with raised sealing faces (Type 2), or flanges with O-ring seals (Type 3), depending on the specific application requirements.

- Dimensions and Tolerances: The standard specifies requirements for the dimensions and tolerances of DIN11853 flanges to ensure compatibility and proper fit with other piping components. This includes parameters such as outer diameter, bolt hole spacing, and flange thickness.

- Materials: DIN11853 flanges are typically manufactured from stainless steel or other materials that are suitable for use in sanitary environments. These materials are chosen for their corrosion resistance, durability, and compatibility with food-grade and pharmaceutical-grade applications.

- Testing Requirements: DIN11853 includes provisions for testing the performance and integrity of flange connections to ensure they meet the required standards for safety and reliability. This may involve pressure testing, leak testing, and other quality control measures.

Related articles

-

Standards for Hygienic Fittings in Dairy & Food Production

-

Designing hygienic process systems : The BS4825 standards

-

Designing hygienic process systems: About stainless steel

-

Designing hygienic process systems: The main coupling types compared

-

Designing hygienic process systems: Tri-clamp ferrule dimensions

Check out our 3D CAD Libraries

Hygienic tubes for the food,beverage and chemical industries. Learn all about materials, sizes, usage and more. Also ALL 3D CAD models here!

DIN-EN Hygienic Fittings and Valves - 700 Fusion FilesDownload this 3D CAD library (3 zip files) and get access to 700 premium quality DIN-EN fittings! (in Autodesk Fusion file .f3d format). |

DIN-EN Hygienic Fittings and Valves - 700 STEP FilesDownload this complete 3D CAD library (1 zip file) and get access to 700 premium quality hygienic DIN-EN fittings! (in STEP file format). |