Premium Quality 3D CAD Files for Your Engineering Projects

3D CAD Files Collections Info for 3D CAD Engineers British Standard BS4825

Designing hygienic process systems : The BS4825 standards

BS-4825: The British standard for hygienic systems

General information about the BS-4825 standards

The British Standard BS4825 is a British standard specifically developed for hygienic tubes and tube fittings used in process installations. This standard is crucial for industries where hygiene is of paramount importance, such as dairy factories, food production and breweries.

Similar to other standards for hygienic tubes, the BS4825 specifies requirements for materials, surface finish, dimensions, and tolerances to ensure consistent quality. These standards are designed to meet the strict requirements of the industry and to ensure the integrity of processes.

The BS4825 is recognized and applied worldwide, although it is originally a British standard. Companies around the world rely on this standard for their hygienic tubes and systems, due to the reliability and proven quality it offers.

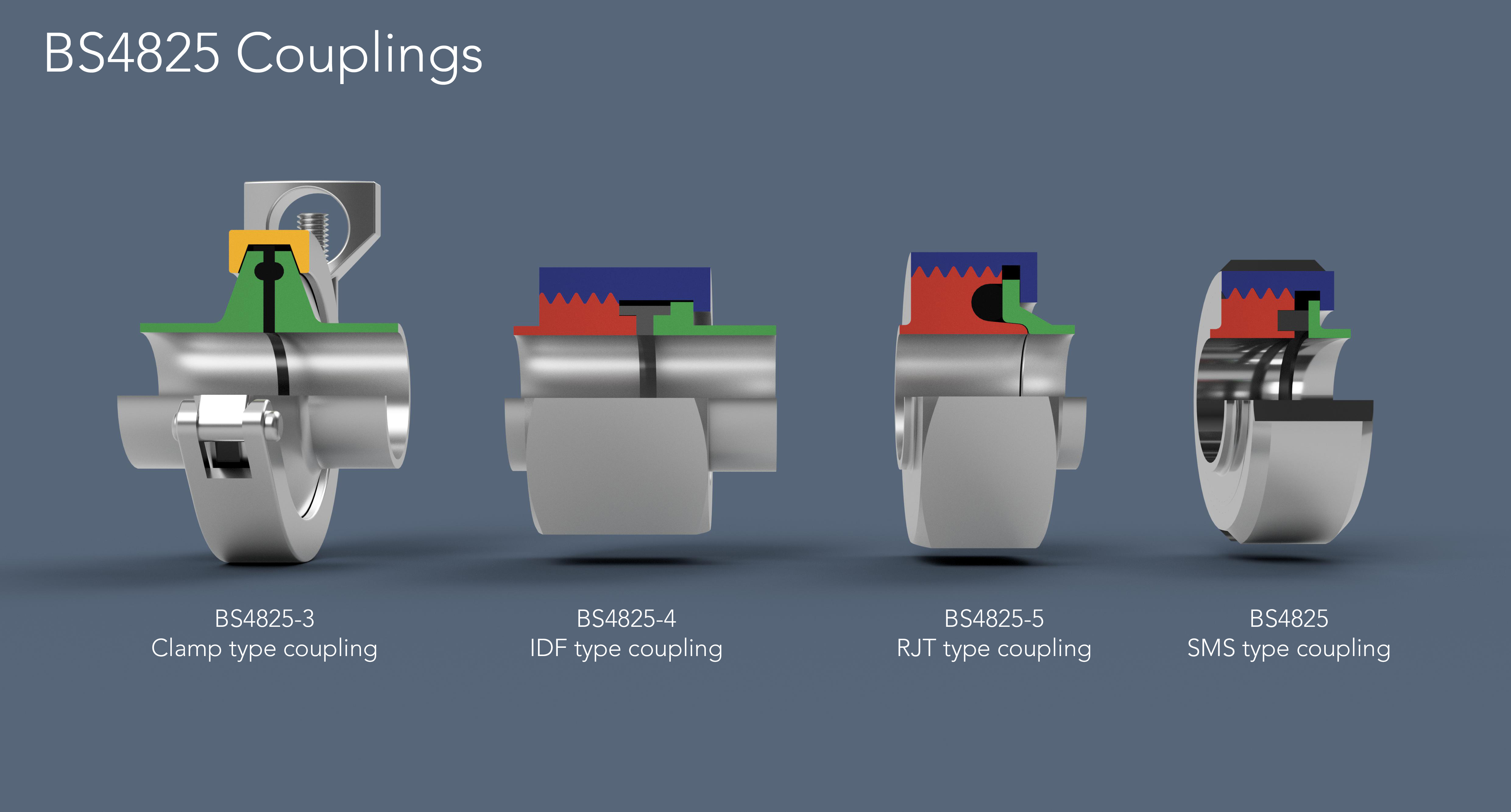

The BS-4825 standards cover several types of pipe fittings, including RJT (Ring Joint Type), IDF (International Dairy Federation), and SMS (Swedish Milk Standard). Each type of fitting has its own specifications regarding dimensions, materials, and finish, designed to meet the unique needs of the industry.

A hallmark of BS-4825 is its emphasis on sanitary design principles, such as smooth surfaces, rounded corners and easy-to-clean construction. These properties minimize the risk of bacterial growth and contamination, ensuring food safety.

The BS4825 standard includes agreements on:

- Dimensions

- Dimensional tolerances

- Material requirements

- Surface finish

- Hygienic assembly of couplings

The BS4825 standard is devided into 5 parts:

- Part 1: Specifications of seamless and longitudinally welded austenitic stainless steel tubes

- Part 2: Specifications for bends and tees

- Part 3: Specifications for clamp type couplings

- Part 4: Specifications of IDF type couplings

- Part 5: Specifications of RJT type couplings.

Besides the coupling types that are described in one of the BS4825 parts, SMS couplings are also often used in British dairy systems. Including welding connections, you have no less than 5 different options for connecting pipes and fittings and that isquite special.

BS-4825 Approved materials

In hygienic production lines, fittings and valves are always made of stainless steel.

The types of stainless stainless steel used for BS-4825 tubes are the following:

|

304 Stainless steel (AISI 304) |

High resistance against rust but susceptible to corrosion from chloride solutions. |

|

316 Stainless steel (AISI 316) |

High resistance against rust and good resistance against chlorides and other industrial solvents. |

Stainless steel 304 is mostly used in the dairy and food sector.

Couplings sometimes use 316 ferrules and male parts, while the nut is made of stainless steel 304.

The benefits of use:

It doesn't matter from which supplier you buy your BS4825 standard parts: the dimensions, materials and quality are always the same.

BS4825 Part 1: Hygienic tube sizes

|

|

| Size | Dimensions D x s (mm) |

| 1/2" | 12,7 x 1,6 |

| 3/4" | 19,05 x 1,6 |

| 1" | 25,4 x 1,6 |

| 1 1/2" | 38,1 x 1,6 |

| 2" | 50,8 x 1,6 |

| 2 1/2" | 63,5 x 1,6 |

| 3" | 76,2 x 1,6 |

| 4" | 101,6 x 2,0 |

Check out our BS-4825 hygienic fittings 3D CAD files libraries

|

|||||

BS4825 Fittings

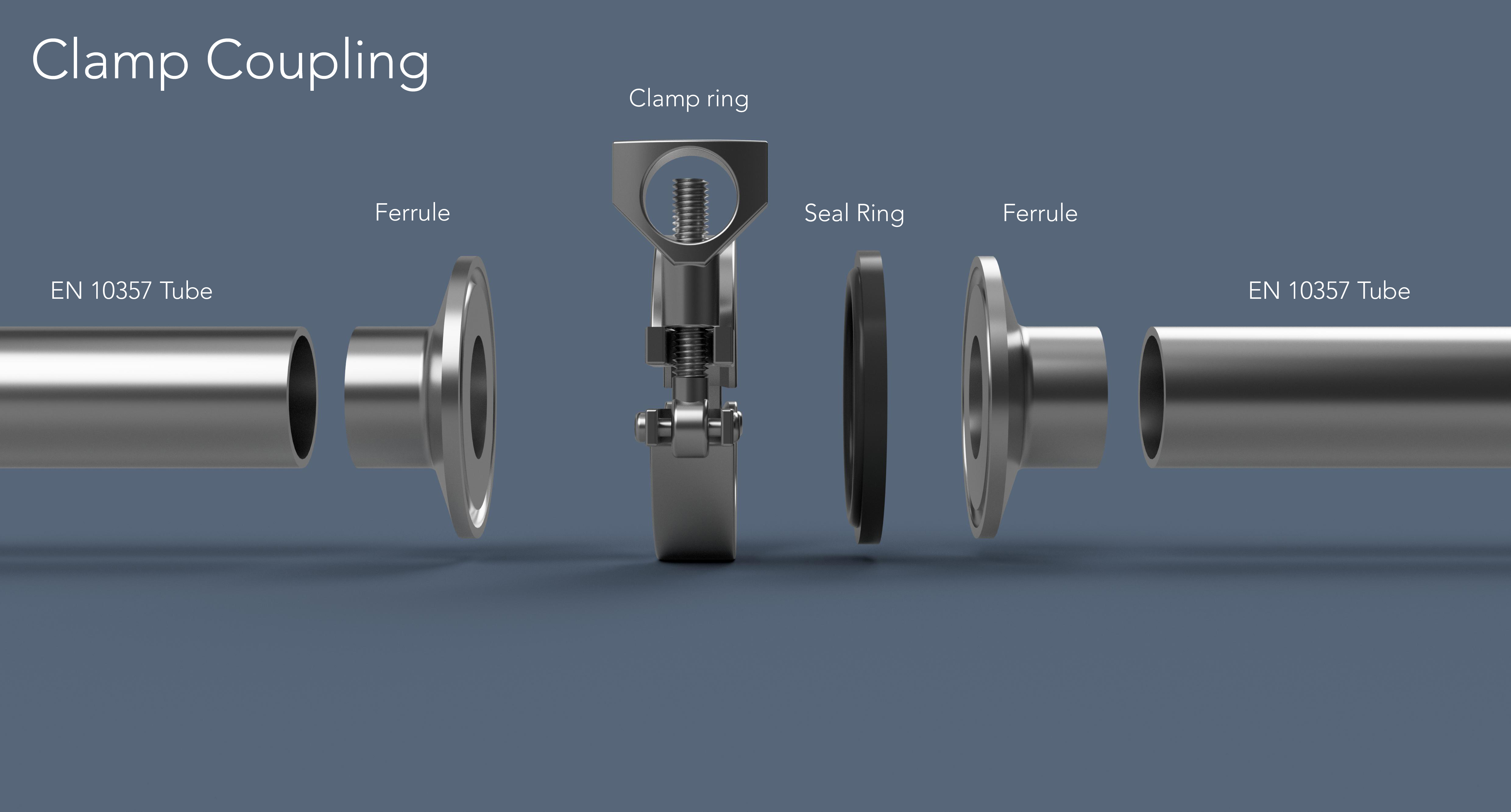

BS4825 Part 3: Clamp type couplings

BS4825 Part 3 clamp type couplings are renowned for their efficiency and hygiene in fluid processing systems. Offering seamless installation and disassembly, they ensure swift maintenance, vital in industries demanding strict cleanliness standards.

Their design emphasizes high-pressure suitability, ideal for diverse applications. However, intricate shapes may pose challenges during cleaning procedures, requiring specialized tools.

Despite this, their exceptional hygiene levels and safety make them indispensable in food, pharmaceutical, and other sensitive industries. Combining reliability with ease of use, BS4825 Part 3 clamp type couplings stand as a cornerstone in maintaining stringent sanitary conditions within fluid handling systems.

| Advantages | Disadvantages |

|

|

|

|

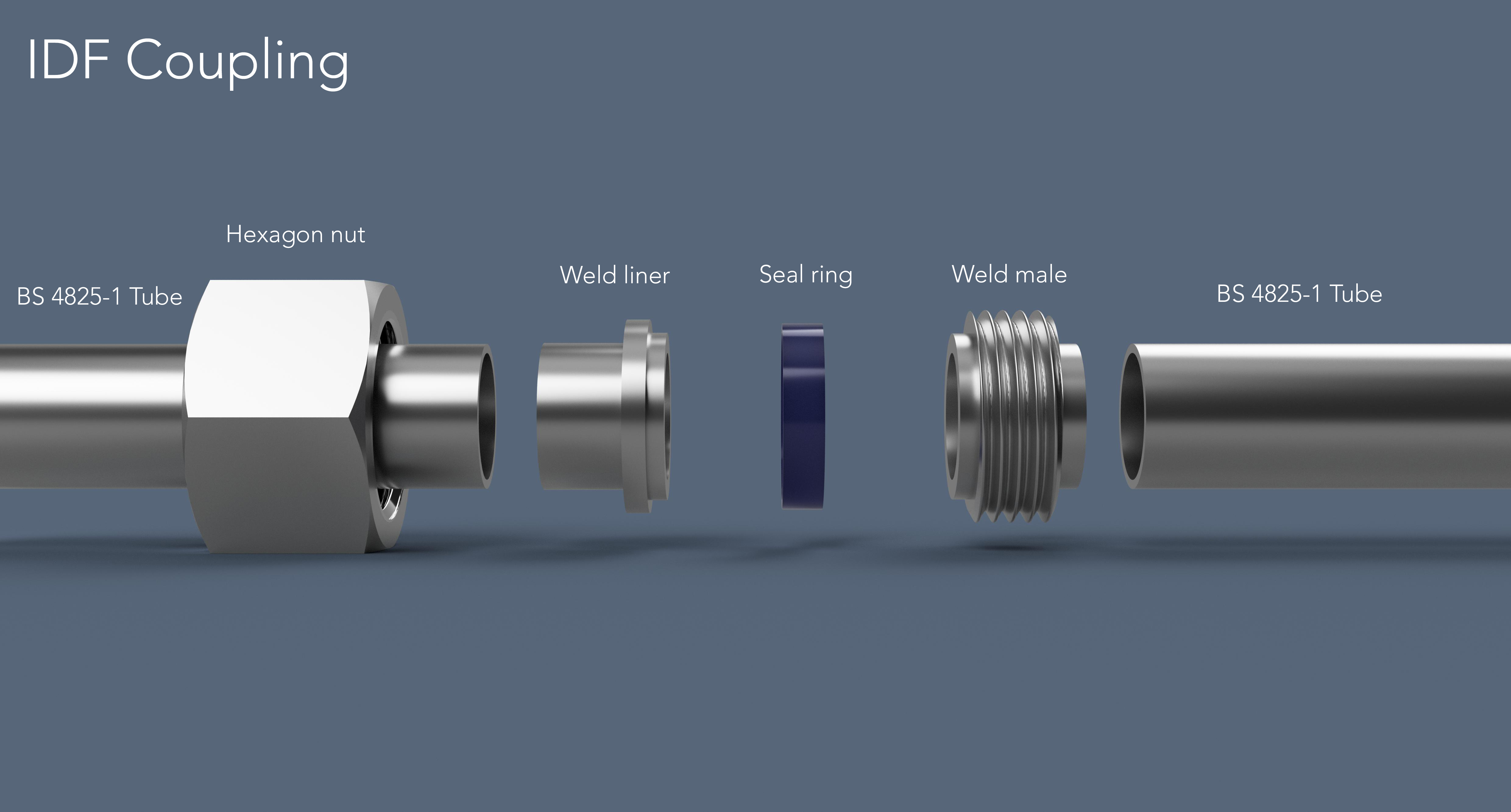

BS4825 Part 4: IDF couplings

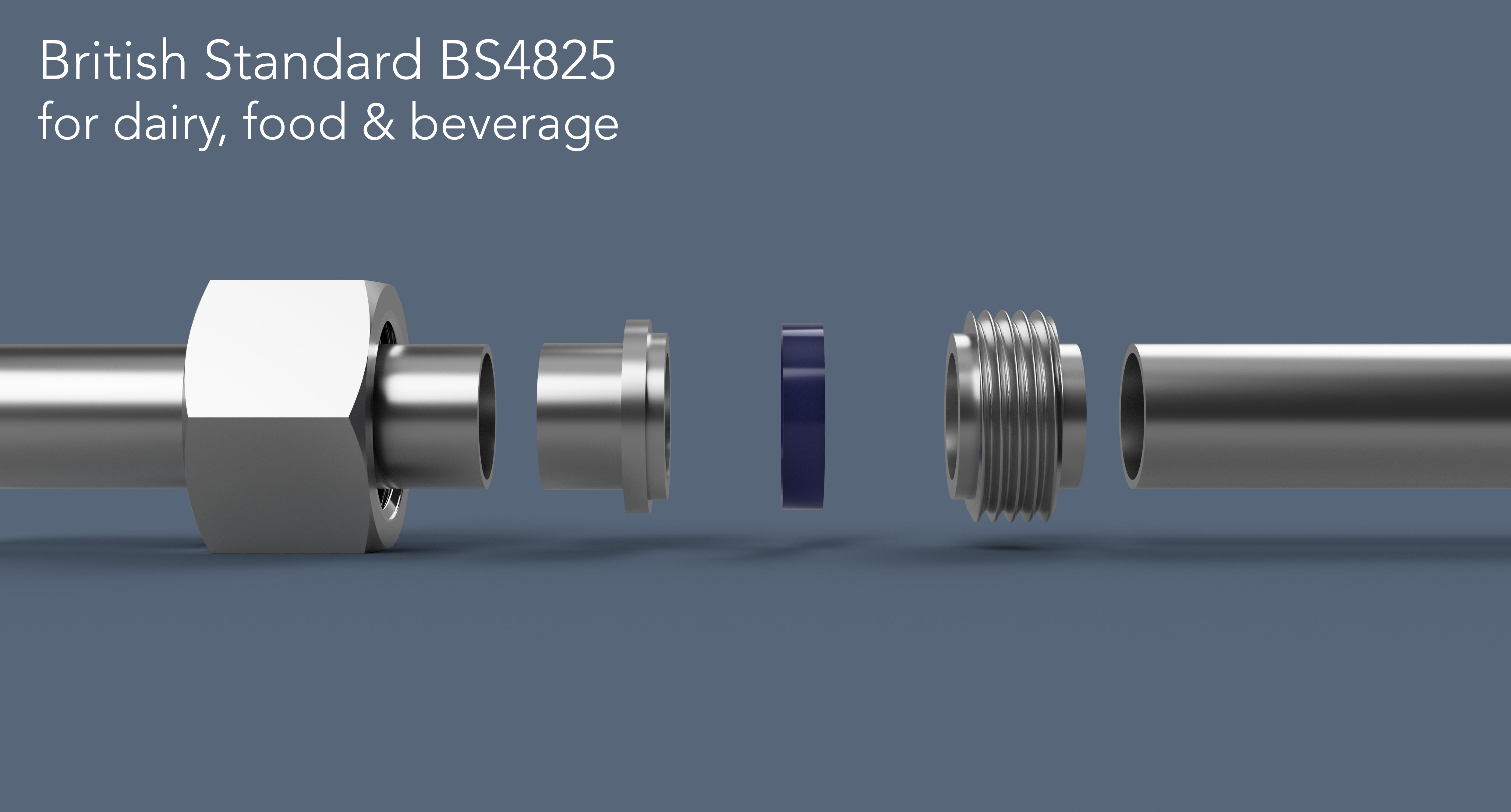

BS4825 Part 4 IDF (International Dairy Federation) couplings represent the epitome of reliability and versatility in fluid processing systems.

Engineered for impeccable sealing and hygienic standards, IDF couplings ensure the integrity of sanitary environments crucial in food and pharmaceutical industries. Their robust design guarantees longevity and durability, making them a preferred choice for demanding applications.

While installation may require more attention due to internal threading, IDF couplings offer compatibility with various pipe sizes and materials, enhancing adaptability. With a reputation for excellence in maintaining hygienic conditions, BS4825 Part 4 IDF couplings stand as an indispensable asset in safeguarding product integrity and consumer safety.

| Advantages | Disadvantages |

|

|

|

|

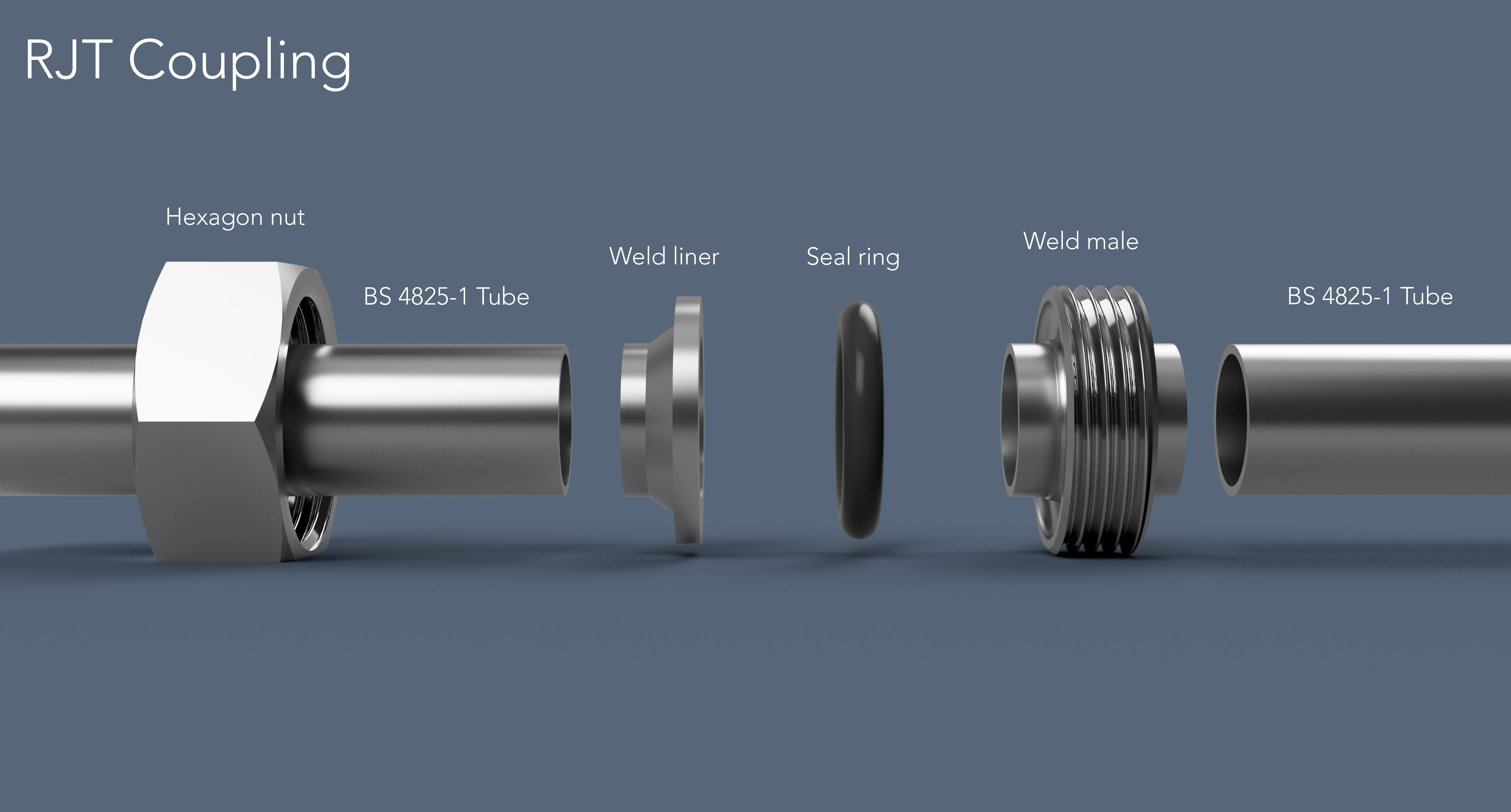

BS4825 Part 5: RJT couplings

BS4825 Part 5 RJT (Ring Joint Type) couplings signify a blend of simplicity and reliability in fluid processing systems. Their hallmark lies in effortless installation and disassembly, facilitating swift maintenance routines critical for operational efficiency.

RJT couplings excel in providing secure sealing even under high-pressure conditions, ensuring leak-free performance in various applications. While not as inherently hygienic as other types, RJT couplings offer versatility, catering to both food and pharmaceutical industries.

However, they may necessitate more frequent maintenance and seal replacements to uphold optimal performance. With their balance of functionality and adaptability, BS4825 Part 5 RJT couplings remain a steadfast choice in fluid handling solutions.

| Advantages | Disadvantages |

|

|

|

|

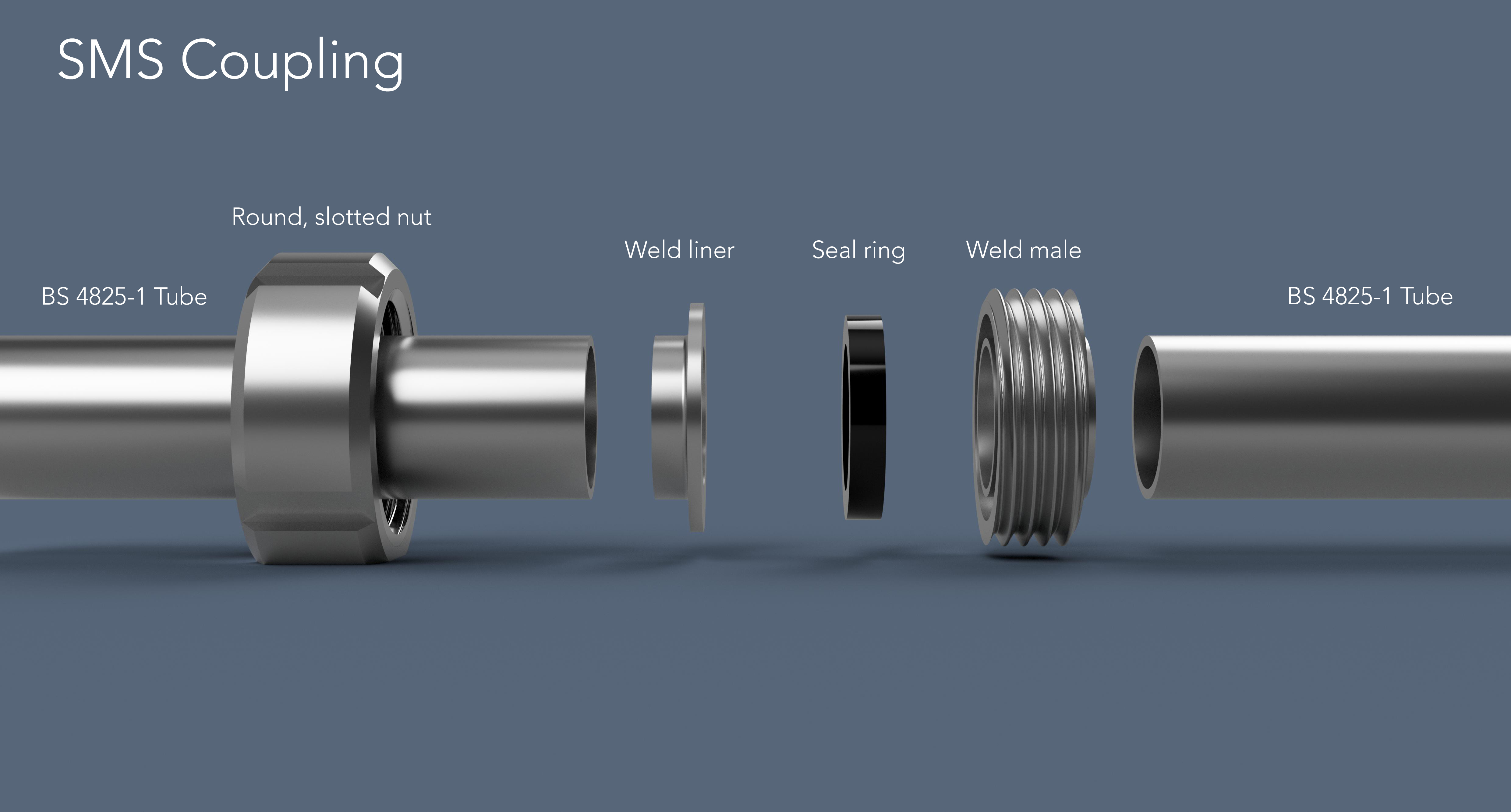

SMS couplings

BS4825 SMS (Swedish Milk Standard) hygienic couplings epitomize efficiency and accessibility in fluid processing systems. With their emphasis on quick and hassle-free installation, SMS couplings ensure minimal downtime during system maintenance.

Despite being less hygienic compared to other options, SMS couplings offer affordability and widespread availability, making them a practical choice for various industries. Their compatibility with standard piping systems further enhances their appeal, providing seamless integration into existing setups.

However, their external threading may pose challenges during cleaning, requiring thorough attention to maintain sanitary conditions. As a cost-effective solution with broad compatibility, BS4825 SMS hygienic couplings remain a reliable choice for fluid handling applications.

| Advantages | Disadvantages |

|

|

|

|

Related articles

-

Standards for Hygienic Fittings in Dairy & Food Production

-

Designing hygienic process systems: The DIN-EN standards

-

Designing hygienic process systems: About stainless steel

-

Designing hygienic process systems: The main coupling types compared

-

Designing hygienic process systems: Tri-clamp ferrule dimensions

Check out our 3D CAD Libraries

BS4825 Hygienic Fittings and Valves - 1000 STEP FilesDownload this complete 3D CAD library (2 zip files) and get access to 1000 premium quality hygienic BS4825 fittings! (in STEP file format). |

BS4825 Hygienic Fittings and Valves - 1000 Fusion FilesDownload this 3D CAD library (7 zip files) and get access to 1000 premium quality BS4825 fittings! (in Autodesk Fusion .f3d file format). |